Shipping containers are the means by which the world moves its goods. “Maritime shipping is the backbone of world trade; it is estimated that more than 80 percent of all goods are carried by sea. In terms of value, global maritime container trade is estimated to account for around 60 percent of all seaborne trade,” according to the statistical information website Statista.com. Statista.com also predicts that the global shipping container market — which was worth $8.7 billion in 2019 — will “surpass the value of 12 billion U.S. dollars in 2027.”

With so much money riding on (and within) shipping containers, keeping their contents safe from theft is a top priority for shippers worldwide. This is why enhancing shipping container security is of prime importance — but how to do it?

To find out, TSI magazine picked the brains of three shipping container security experts.

Bill Schoenherr is vice president and general manager of NovaVision. It is a technology company that specializes in anti-tampering and anti-counterfeiting products such as hologram labels, tamper evident stickers, security tape, and mechanical security seals. “We conduct business globally and have over 5000 active customers each year,” said Schoenherr. “Our major customer groups include governments (U. S. A. federal, state, county, municipal and international), large international companies, retailers, and collectible companies.”

Greg Miner is Conexwest’s operations manager. “Conexwest is one of the leading container providers in the US,” he said. “We supply rental, and sale containers. We also specialize in the manufacturing of custom built containers.”

Robert Lindyberg is CEO of Global Secure Shipping (GSS). His company “provides comprehensive cargo security solutions developed by the University of Maine in partnership with the U.S. Department of Homeland Security, (DHS) under the U.S. Department of Defense (DOD) Title III Defense Production Act, and industry leaders,” said Lindyberg. “GSS is the primary commercial partner in a federally-funded, multi-year Collaborative Agreement with DHS, DOD, UMaine, and Georgia Tech Research Institute to produce the Secure Hybrid Composite Intermodal Container (SHCIC) – also called the Global Secure Container.”

Here’s what they told us.

Threats to Shipping Containers

Given the global scope and multi-billion-dollar value of shipping container-based trade, it is not surprising that “the industry as a whole has many threats,” Miner told TSI magazine. “Take a construction site, for example. You have people who will either cut the container and enter through the side walls, cut through the lock rods on the front, or even go as far as trying to pull the lock rods off by attaching a chain to a truck and driving away.”

According to Schoenherr, the most common theft-related security violation experienced by NovaVision customers is having legitimate ‘security seals’ removed from their shipping containers and replaced with poorly-made fakes. “The criminals often do not bother to match the original serial number,” he said. In the number two position: “Security seals are attacked physically in an attempt to remove and reuse the original seal (no change in the serial number).”

The third most common security violation occurs when “container doors are physically removed at the hinges without disrupting the original security seals,” said Schoenherr. “After goods are removed, the hinges are reattached.” And finally, the number four most common crime is when “security seals are replaced with a counterfeit with matching serial numbers.”

All of these violations can occur when thieves open shipping containers, steal their contents, and then try to cover their tracks.

These threats to shipping container security were serious enough prior to the pandemic. Since then, “the shipping and supply chain disruption initiated by COVID-19 has resulted in major problems including bottlenecks at major ports and increased dwell times at unsecured railroad depots, increasing the risk of container break-ins, theft, and/or loss,” Lindyberg said. “In September 2021, the dwell time for containers at 11 major railroad depots was an average of 9.8 days, up from 5.9 days in February.” The longer a shipping container sits at an unsecured location, the more time thieves have to loot it.

But have these extended dwell times actually resulted in more thefts from shipping containers? On this point, opinions are mixed.

“Yes, especially for high value goods,” said Schoenherr. “The National Insurance Crime Bureau reports that there are over 8,500 thefts annually resulting in over $15 billion in losses in the US.”

“I don’t necessarily think they have been on the rise,” countered Miner. “I do believe that with the container gaining more popularity and being used in so many different ways, that there are more opportunities for these types of break-ins/theft.”

A Range of Security Solutions

Theoretically, it is possible to deter theft from shipping containers by ringing them with armed checkpoints and constant patrols conducted 24 hours a day. Practically, this level of security is not economically viable because of the exorbitant cost and logistical issues it would add to the shipping process – especially if the container’s contents are of relatively low value and therefore not attractive to most thieves.

This is why “there are lots of different levels of security” when it comes to shipping containers, Miner observed. At Conexwest, “we place lock boxes on all of our rental containers,” he said. “This acts as a secondary means of entry, and will deter most who try to enter the container through the lock rods.”

To protect more valuable contents, Conexwest customers can use an ISO Heavy Duty Lock on their container doors. “It is a lock that clamps onto the lock rods and has a keyed point of entry,” said Miner.

NovaVision takes a graduated approach to shipping container security. The tactics it recommends are designed to correspond to the value of the goods inside specific containers, based on a ‘risk assessment’ of their attractiveness to thieves and how secure their physical locations are. “For example, low value shipments in low-risk areas may only require a single security seal,” Schoenherr said, “while high value shipments may require multiple layers of security, especially in high-risk areas.”

To aid TSI readers in choosing the right security defenses for their shipping containers, Bill Schoenherr compiled the following four options listed in order of increasing security and supported by explanatory photographs.

In the most low-risk scenarios, “the door latch/lock can be secured with a Bolt Seal or Cable Seal,” he said.

To add another layer of security in more risky situations “and to protect both container doors, also wrap the locking rods with another security seal,” said Schoenherr. “This can be accomplished by using a single cable seal with a 76” long cable, which can secure both the latch and wrap the locking rods. Some security seals include multiple independent locking mechanisms (a bolt and cable seal combined or two independent locks on one cable seal), which in addition to convenience of use, offer more security because the seals are unique and two cuts are required to gain access to the shipping container.”

For situations where more protection is required, Bill Schoenherr recommended adding a ‘barrier seal’, which is a heavy-duty mechanism that shackles the two locking rods together. “This offers more security because it requires special cutting tools to remove,” he explained. “The removal process requires more time and the special removal tools (grinders, et cetera.) create more noise,” making it harder for the thieves to go undetected on site.

For an even higher level of shipping container security, “you can include ‘Cargo Door Seals’, which are extra-large (typically 3” x 12”) tamper evident labels,” said Schoenherr. “These cargo door seals can be used in conjunction with the other security seals and can be applied in other vulnerable areas such as across the opening seam of the two swing doors on the container, and over the hinges of each swing door on the container.”

If needed, place your shipping containers in securely fenced-in outside areas or inside locked warehouses, with CCTV camera coverage, motion detection and regular patrols. But again, this level of security is only justified if the contents are of high enough value (and easy enough to ‘fence’) to offset the extra cost.

Tracking and Tracing Solutions

In today’s connected world, shipping container security can be bolstered by tracking and tracing solutions.

Some of these solutions are simple, but they do the job. A case in point: At NovaVision “our seals use serial numbers and barcodes,” Schoenherr said. “Having the security protocol and discipline to track the serial number is very effective.”

At Conexwest, “there are GPS systems that exist for the rental fleet, plus tracking devices,” Miner said. Again, discipline and consistent adherence to proper procedures are required to make them work. “The biggest issue with the tracking devices is that there is a lot of data entry that corresponds with them,” he said. “If it isn’t handled correctly, it doesn’t do any good.”

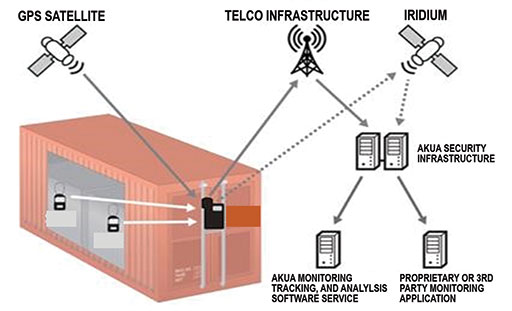

On a more complex level, GSS and partner AKUA are providing “tracking and security solutions for intramodal shipping containers that are fully effective across all modes of shipping,” said Lindyberg.

For instance, “GSS’s Global Secure Container is CSC/TIR certified, and provides six-sided security against unauthorized door opening, or penetration of the walls, door, roof, or floor,” he said. “Coupled with the AKUATrack system, this solution provides the shipper with container location and security status, delivering full, end-to-end supply chain tracking and monitoring.”

Dealing with and Deterring Corrupt Employees

Even the most secure shipping container is at risk from corrupt employees. This is why shipping companies need to take steps to detect such employees within their ranks and deter them from taking illegal actions when opportunity arises.

Spotting potential thieves during the hiring process is a good way to keep them and shipping containers safe. However, “in addition to initial background checks, periodic background checks (every two or three years) for existing employees can highlight possible criminal activity, plus it sends a strong message to the employees,” Schoenherr explained. “If the background check includes financial information, the company can better understand if employees are experiencing financial hardships, which can be a motivator for temptation.”

Random drug testing can also highlight employees at risk, he added. “An employee on drugs may require an infusion of cash to maintain the habit and the company is a convenient target, especially if its shipping containers have contents of high value that are easy to resell.”

“While it is very difficult to thwart all corrupt employees, having a security protocol and discipline to track the serial numbers can discourage many ‘inside jobs’,” Schoenherr noted. “Periodic meetings with employees to discuss security measures and re-train on procedures can also be helpful.”

Advice to Readers

To conclude this look at enhancing shipping container security, TSI asked the experts to provide some last words of practical advice.

Greg Miner’s advice was short and to the point. “Place a lock box on your container and have multiple locks; one inside the lock box and one on the latches,” he said.

Bill Schoenherr’s advice was more detailed.

First, shipping container users should make periodic risk assessments and base their security protocols on those assessments. “The risk assessment should also include the full delivery cycle,” Schoenherr said. “With the current supply chain disruptions, shipping containers are at risk for longer periods of time — including extended storage at ports and warehouses.”

The level of risk should be determined based on the entire shipping process, he added. “We highly recommend assessing your risk based on supply chain issues, your company’s protocols and the product being moved through the supply chain. For instance, high value/high risk items like electronics and pharmaceuticals may require additional levels of security than a lower value cargo.”

Next, shipping container users should be open to employing all security options. “While a high security bolt seal is good at a minimum, there are better levels of security seals as previously stated that protect both doors of a container, cable seals and locking bar seals,” said Schoenherr. When the contents are sufficiently valuable, nothing is off the table.

For cross border shipments, NovaVision recommends using high security (H) seals, which have been certified to ISO17712. “A requirement for ISO 17712:2013 is that all ‘H’ seals must be independently tested at least every 24 months,” Schoenherr said. “Ask the supplier of your bolt, cable and barrier security seals to provide the manufacturer’s written verification that the seal was independently tested to comply with ISO 17712:2013 as a high security seal. To meet the ISO standard, the testing and certificate must be dated within 24 months of your purchase.” (Note: All of NovaVision’s high security cable seals, bolt seals and barrier seals are certified to ISO17712.)

“Customized seals offer more security than standard seals,” he added. “Changing up your security seals or layering different solutions is a good way to remain ahead of the counterfeiters.”

Finally, shipping container users should conduct random security audits to ensure compliance with their protocols, both with their own staff and third parties who handle containers on their behalf.

Taken as a whole, all of these options can enhance shipping container security. Granted, no security system is perfect, but taking steps to enhance your own can persuade thieves to look for easier targets elsewhere.