According to the data analysis site www.Statista.com, “some 80 percent of all goods are carried by sea. In terms of value, global maritime container trade is estimated to account for around 60 percent of all seaborne trade, which was valued at around 14 trillion U.S. dollars in 2019.”

Given the primacy of maritime cargo carriage, it isn’t surprising that shipping is a top smuggling choice for criminals. Their illegal goods include narcotics, endangered animals and plants, prohibited weapons, toxic chemicals, and anything else forbidden by law that people will pay dearly to possess.

It is up to port authorities and police to detect as much of this contraband as possible. Although human searches and sniffer dogs remain common, advanced X-Ray scanners are increasingly being used to execute accurate and detailed maritime cargo searches. This is good news, because the ways in which criminals smuggle in goods inside containers and other objects keep increasing in creativity and sophistication.

How X-Ray Scanners Are Used

The goal in scanning maritime cargo is to minimize the disruption of the cargo handling process, while maximizing the ability to detect contraband in its many forms. This is why two types of X-ray scanners are generally used. The first type is enclosed flowthrough scanners that allow specific packages and boxes to roll past a X-ray scanning unit, which are also employed at airports to screen baggage. The second type is passthrough scanners large enough to allow a truck and/or shipping container to drive through.

In both instances, the contents are scanned by X-ray equipment that is far beyond the medical versions that relied on film decades ago. Instead, modern X-ray scanners collect their data using electronic sensors and software that display the results on computer screens, in colors and at levels of detail that precisely reveal what’s inside.

The decision on which types of x-ray scanners are chosen to screen maritime cargo depends on their location and mission. Generally, they are variants of the passthrough model.

“At the entrance/export location of the port for incoming and outgoing maritime containers, we advocate use of passthrough (portal) X-ray scanners at a fixed location,” said Kevin Davies. He is Global Director of Ports and Borders for Smiths Detection, which designs, manufactures and distributes detection/ screening technology to airports, borders, and ports, among others. “These scanners are configured to control and manage a high throughput of container traffic, without disrupting the traffic flow.”

Such fixed scanners are generally integrated into controlled truck/container roadways. These units automatically scan containers while avoiding the drivers’ cabins. The Smiths Detection solution for passthrough X-ray scanning is based on its HCVP product line. It can process more than 120 containerized trucks per hour.

When it comes to scanning maritime containers during intermodal transshipment — e.g. when they have been removed from ships and placed onto train or truck flatbeds — portable versions of the passthrough scanner are brought on-site to check container contents. They are typically used inside the port at a dedicated ‘area of control’, usually within the container terminal handling area. “One Smiths Detection system for such a situation is the HCVM,” Davies told TSI magazine. “It has the ability to inspect the vehicle in both passthrough scanning mode (acting as a stationary Portal) or in Mobile mode where the system passes over a stationary container.”

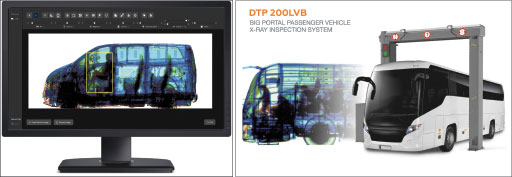

LINEV ADANI is another global designer/manufacturer of X-ray scanning systems that detect contraband. Its DTP 200 line of passthrough X-ray portals are scaled to handle everything from cars and vans to passenger buses and transport trucks (both self-contained and carrying containers). LINEV ADANI’s ‘Trainscan’ is large enough to X-ray entire freight trains as they drive through!

“There are two main uses of these systems,” said Rob Keeler, sales director and general manager at ADANI Ltd. (LINEV ADANI’s UK division). “The first is to ensure that the contents of a cargo container/lorry are as expected from the details on the manifest. The second is to check for contraband – which may be drugs, tobacco, alcohol or firearms – hidden within the cargo or vehicle.”

By providing real-time high quality images of a container/truck’s contents, the port authority/police can effectively ‘see’ what’s inside without going inside. This kind of search can be done in under a minute. In contrast, “If a Customs official decides to manually search a 40’ shipping container, then typically this will require between 10 and 30 man hours of labor,” Keeler noted. “Being able to scan cargo this quickly means that Customs resources can be focused on suspect cargos on a widescale basis, rather than randomly selecting a very small percentage for checking.”

Astounding Levels of Detail

It is not just the speed and ease-of-use offered by X-ray scanners that makes them so useful for screening maritime cargo. It is also the level of visual detail that is captured by these devices —detail recorded in digital files that can be reviewed by multiple experts and used as inconvertible evidence in court if need be.

This precision is enhanced by sophisticated scanning algorithms that analyse the data generated by X-rays shot at different angles to create highly-detailed and informative 3D images. Known as Computer Tomography (CT), this methodology helps create the astoundingly accurate X-ray scans being used to detect contraband today.

Integrated Defense and Security Solutions (IDSS) is one such CT-focussed scanning design/manufacturing firm. “IDSS has incorporated algorithms for enhanced security for explosives detection and the development of Artificial Intelligence algorithms for the detection of prohibited items and narcotics,” said Jeffrey Hamel, IDSS’ CEO and president. “We will continue to enhance the capability of CT systems for years to come in a variety of applications.”

IDSS’ expertise in CT X-ray scanning resulted in the company winning the $500,000 Grand Prize in the Department of Homeland Security’s Opioid Detection Challenge. (This is part of a $1.55 million global prize competition for rapid, nonintrusive detection tools to find illicit opioids in international mail.) IDSS won this award on the basis of its IDSS DETECT 1000 solution. Combining CT scanning with automated detection algorithms, the IDSS DETECT 1000 identifies anomalies in X-ray images based on the scanned item’s features and physical properties.

This company’s new, larger DETECT CS320 is aimed at the cargo scanning market. “It utilizes the same underlying technology as our award-winning DETECT 1000 platform currently deployed at points of entry for scanning of flat packs and express parcels,” Hamel said. “We will be able to leverage our experience winning the DHS challenge to train our algorithms to see inside the pallets looking for anomalies and automatically detect contraband.”

High image resolution is also a hallmark of the X-ray scanners made by Smiths Detection. “Thanks to our scanners and the technology behind them, the smallest detail, such as the spokes of the wheels of a bicycle, the drive chain of a motorcycle or the shape of an individual bottle, are clearly seen on a X-ray image within a fully loaded 40’ container,” said Davies. “A standard 20-feet maritime container can be loaded with more than 20 tons of goods. Thanks to our X-ray system systems and some of the AI/ML tools we incorporate, a few kilograms of illicit substances or gold can be easily identified by the trained operator.”

The same high level of visual precision is also provided by LINEV ADANI’s X-ray scanners. “Given the size of maritime cargo — often a full 40’ container for those that have never seen it — the detail that can be identified on an LINEV ADANI Vehicle/Cargo Scanning System is much better than would be expected,” Keeler said. “You have the ability to detect wires of much less than 1mm diameter and very small contrast differences. Plus the LINEV ADANI systems offers a wide range of Operator Image enhancement tools; not just zoom, contrast, brightness and the obvious ones but some very sophisticated Image Enhancement Algorithms to optimise the detection of contraband.”

Looking for What Shouldn’t Be There

When it comes to analysing X-ray scans, the algorithms employed by these companies are always on the lookout for ‘anomalies’ — artifacts within the image that may indicate the presence of contraband. “Often these are identified when compared to the quantities declared validated against the imagery either by the human operator and/or the AI/ML (machine learning) algorithm which delivers results to the operator,” said Keeler. “This is how the X-ray images delivered by LINEV ADANI’s product line assists greatly the probability of detection whether it be for smuggled illicit goods, contraband or the simple validated identification of declared goods.”

Another method for catching anomalies is to marry passthrough X-ray scanners with other devices such as Automatic Number Plate Recognition (ANPR), Automatic Container Code Recognition (ACCR), Cargo Manifest Systems (CMS) and Radiation Detection Systems. This marriage allows the port authority/police not only to detect contraband, but also ensure that the contents that are in the container/truck’s manifest are actually what’s on board.

Foiling Smuggling Strategies

There’s an old truism in business: The policies developed by companies that restrict the actions of their customers and limit corporate liabilities to them are direct responses to previous customers trying to take advantage of the system.

The same is true for anti-smuggling technologies. Today’s level of electronic detection sophistication is a direct response to sneaky smuggling strategies.

According to Kevin Davies, there are several common ways to smuggle contraband inside a maritime container. “One is the ‘rip-off’, which refers to adding a few bags with contraband just behind the doors of the container at its entrance — easily seen on the X-ray image,” he said. “Another one is to modify the container to allow contraband to be concealed inside the roof, the ceiling, the sides and the door or the flooring. We have developed an iCMORE AI algorithm to automatically highlight and survey such areas. Smiths Detection scanners are able detect and defeat such concealment methods due to their ability to deliver great image quality.”

A third method is to hide the smuggled goods at the back of the container, behind the legitimate declared shipment. Again, this concealment method is no match for modern technology. The scanner’s contrast sensitivity and its ability to deliver accurate X-ray images even when shooting through a large legitimate shipment means that contraband still gets found in unopened containers.

If this isn’t enough, IDSS’ DETECT CS320 CT technology generates high-resolution, fully-rotatable 3-D images of container interiors, which allows port authorities and police to examine the contents from many angles. Faced with this level of contraband detection, “many smugglers will change their routes to avoid advanced screening technology and inspections,” said Hamel, “since it becomes more difficult to disguise cargo and be successful in smuggling contraband.”

Advances to Come

Today, the level of X-ray scanning technology is impressively capable of detecting maritime contraband. But coming advances in this technology are going to make life even tougher for the world’s smugglers.

According to Rob Keeler, the areas that will change in cargo inspection/screening are twofold. First, there will be “improved integration of ‘subsystems’ so that the operator has more information about what should be in the cargo,” he said. “This will maximize the ease of identifying suspect areas.” Second, Keeler expects further improvements to be made to image quality and Suspect Area identification, aided by the use of AI-enabled analytics.

“The main challenge is to be able to cope with the quantity of cargo that is being shipped around the world,” said Keeler. “This is growing year on year at a fast rate, so system throughput is critical to ensure that a significant percentage of cargo can be checked without causing unacceptable delays.”

Kevin Davies foresees advances being made by adding more automation to cargo inspection locations. This will minimize disruptions and ensure the efficient movement of containers/trucks through ports and their associated terminals while enhancing contraband detection. The interconnectivity and interoperability capabilities of today’s X-ray scanner systems will allow them to connect seamlessly into a wider ‘Big Data’ network inspection process, he said.

Even today, “automatic identifications of containers through our systems are provided to users along with the manifests of load and the verdicts of the X-ray scans allocated by the operator or system,” Davies noted. “An interconnection (via Electronic Data Interface) between the scanner system and the traffic control system of the port is also commonly being implemented to bring efficiency to port operations and streamline container flows.” In the future, he predicted that a centralized Image Analysis/Verdict Room may be established to share X-ray image analysis between a team of experts and to link multiple X-ray systems to a single Command and Control center.

The bottom line: X-ray scanning technology is making it much harder for smugglers to slip maritime contraband past port authorities — at least who have invested in such technology. As Jeffrey Hamel suggested, this fact may motivate smugglers to put more focus on moving illicit goods through smaller, less secure ports, rather than wasting their time trying to beat modern X-ray scanners.

Leidos Offers Vision into Inspection Capabilities

Reston, Virginia-based Leidos, a Fortune 500 information technology, engineering, and science solutions and services company, is working to solve challenges in the defense, intelligence, civil and health markets. We spoke with Matt Guillebaud, product management lead at Leidos, about their inspection and scanning products and their laser-focus on helping meet the rapidly changing needs of the industry.

Q: What kinds of inspection technology does your company provide for inspecting/scanning maritime cargo at ports, and how does it work?

A: Our VACIS systems scan cargo containers, trucks, railcars, buses, and passenger vehicles to help authorities search for narcotics, weapons, nuclear material, undeclared goods and other contraband at ports of entry, border crossings, military facilities, and other checkpoints. For example, in April 2021, Leidos was awarded a prime contract by the U.S. Customs and Border Protection (CBP) to provide Multi-Energy Portal (MEP) systems for non-intrusive inspection (NII) of commercial vehicles at land and seaports of entry. The MEP systems will be integrated in Vista, California, and deployed to existing vehicle inspection sites across the U. S.

Under this contract, Leidos will integrate, deploy and train CBP staff to use its VACIS MEP with low-energy backscatter and high-energy transmission cargo inspection system. This work will incorporate the VACIS IP6500 and Viken Detection’s OSPREY-EVXTM and OSPREY-UVXTM. The system includes a QR code reader, license plate recognition (LPR) technology, a radio frequency identification system (RFID), situational awareness cameras and an open-standards interface to the DHS SWIFT system. It is also capable of integrating radiation detection equipment (RDE).

Q. What are some other real-life examples of where your systems have been used?

A: Leidos systems were used during the Presidential inauguration and the Super Bowl. During the Presidential inauguration, CBP deployed two Leidos mobile high-energy M6500 systems, as well as two VACIS XPL low-energy POV systems, at Robert F. Kennedy Memorial Stadium, where responder equipment and personnel were located. At Super Bowl LV, CBP deployed two M6500s to screen commercial delivery trucks and vans for weapons, explosives and other contraband, using advanced inspection technology.

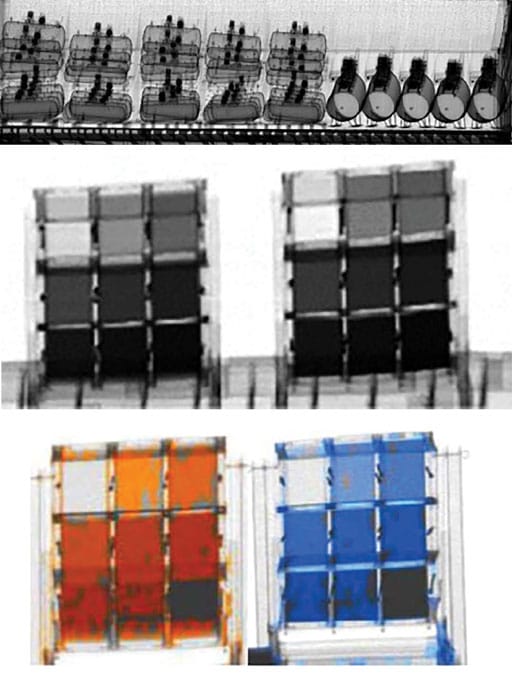

The figures in middle and bottom images show VACIS IP6500 scans of containers containing both predominantly organic and predominantly metallic materials without material discrimination (single-energy X-ray), showing different degrees of absorption as different shades of gray, and the same containers imaged with material discrimination (dual-energy X-ray), showing different Z values in different colors. By examining both images, inspectors can identify cargo anomalies more accurately than would be possible using either image alone.

Q: How detailed are the inspections that your technology can perform?

A: Our VACIS integrated cargo inspection systems combine high-energy X-ray imaging with optional integrated radiation scanning and equipment identification (OCR or LPR) to help authorities inspect containers for nuclear material, weapons, hazardous material, contraband, undeclared cargo, and other items of interest. We use a compact, high-energy X-ray source and extremely sensitive detectors to produce high-quality digital images of the contents of vehicles and containers, using a very low radiation dose. Because of this low radiation dose, the systems require no shielding outside their portal structures, and their controlled-access areas are only slightly larger than the systems themselves.

Our systems offer true material discrimination capability. The systems measure the relative absorption of two X-ray energies to estimate the atomic number (Z) of the various materials in the vehicle, and display different Z values in different colors. This feature helps inspectors identify drugs and currency (low-Z organic material); as well as guns, ammunition and other weapons (high-Z inorganic material). Systems with single energy X-ray are unable to provide this feature.

The figures below show VACIS IP6500 scans of containers containing both predominantly organic and predominantly metallic materials without material discrimination (single-energy X-ray), showing different degrees of absorption as different shades of gray, and the same containers imaged with material discrimination (dual-energy X-ray), showing different Z values in different colors. By examining both images, inspectors can identify cargo anomalies more accurately than would be possible using either image alone.

Q: How are cargo control authorities using your equipment to inspect cargo, and what are they looking for?

A: Customs/border control agencies are faced with the challenge of balancing national security with economic interests, i.e. facilitation of legitimate trade and travelers. Our fixed and mobile imaging solutions and radiation detection portals provide them with the tools they need to identify contraband or nuclear material (i.e. weapons to narcotics) while also allowing border officials to rapidly assess the legitimacy of a cargo shipment.

As trade volumes increase, the demand on speed and quality of cargo inspection is driving the need for Artificial Intelligence (AI) algorithms to assist border authorities processing larger volumes of cargo while maintaining the quality of inspections. AI assisted analysis promises to assist border officials by accelerating the customs clearance workflow and by identifying anomalous items in cases where the human eye cannot.

Q: How does your equipment help them detect contraband? Are there any specific stories that you can share that are related to this?

A: Imaging equipment is part of a layered approach to border security that helps to mitigate risk. Our customers use Leidos solutions in combination with their own intelligence systems that perform advanced screening of cargo and passenger data, officer experience and intuition, and other intelligence information, to achieve a complete security and trade facilitation posture. We cannot share agency seizure data, but can generally say that our equipment has helped officials to seize tons of illegal narcotics, weapons and bulk cash that all are part of disrupting international criminal organizations all while ensuring the flow of legitimate trade.

Q: What steps do smugglers/arms dealers take to disguise contraband cargo, and how does your technology detect it otherwise?

A: Smugglers have no limit to their creativity. They are always adapting to interdiction methods and tactics used at the border. As such, we have a responsibility to adapt and enhance our equipment and ensure that it is as flexible as possible for our customers. We do this in a number of ways. We ensure that our cargo scanning portals require little to no civil works (concrete) so that our systems can be rapidly deployed or relocated. Also, our detection algorithms are trained to identify anomalies in cargo that may not be apparent to the human eye, assisting customs officials to detect small quantities of contraband concealed within a large quantity of other cargo in a container.

Smuggling techniques evolve but so does technology. Artificial intelligence is providing new ways for us to increase the performance of our imaging and radiation detection systems as well as assisting our customers in identifying contraband or confirming legitimate trade. In conjunction with our strategic focus on AI, we are focused on providing the most cybersecure scanning systems and software platforms. Most importantly, we work side-by-side with border agents to understand their specific needs and ensure that we are responding with the most effective capabilities. Sometimes, that requires teaming with other key technology suppliers as we have recently done with Viken Detection

Q: What advances are coming in cargo security inspecting/scanning, and what new challenges are arising as well?

A: The convergence of cybersecure and operationally resilient enterprise software platforms with AI-assisted analysis algorithms are going to accelerate and force-multiply customs operations soon. These are strategic focus areas for Leidos. We are deploying our Leidos Enterprise Application Framework (LEAF) for a DHS Common Viewer pilot this year, the most secure and flexible enterprise-grade common viewer system available for Customs agencies. We are also working with several Customs agencies to test AI-assisted analysis algorithms for threat detection and manifest verification in operational environments. These two technologies will allow Customs agencies to centralize and leverage their scan data, correlate scans with other internal data sources, apply AI assistance at scale, and deliver that information anywhere within their organization.