Technology to control the import or export of shipping containers, detect hidden contraband and verify the crossing of legitimate trade items is advancing.

Approximately 12 million maritime containers arrive at U.S. land borders every year, according to the U.S. Customs and Border Protection (CBP). The seaports take in an equal number, and 2.7 million arrive by rail. CBP’s mission is to protect America and the American people from incoming threats.

After the 9/11 attacks, U.S. Customs Service created the Container Security Initiative (CSI), an anti-terrorism program. CSI proposes a security regime to ensure all containers that pose a potential risk for terrorism are identified and inspected at foreign ports before they are placed on vessels destined for the United States. This can include contraband such as illicit drugs, illegal imports, weapons and nuclear materials.

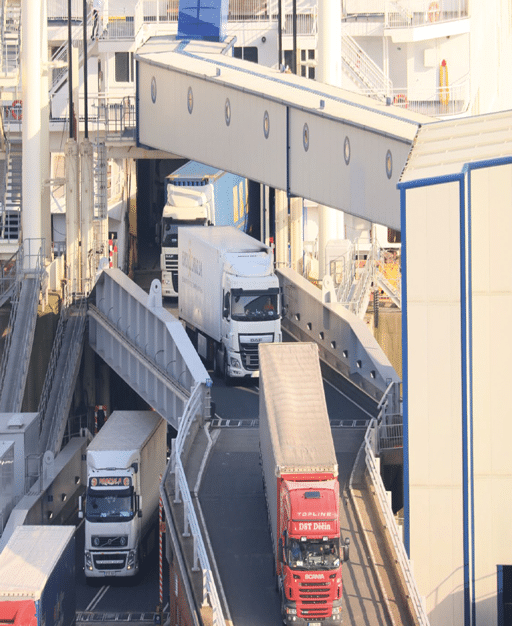

“Cargo containers, whether moved by ship, train or truck, provide a convenient means to transport illicit items,” says Mathieu Guillebaud, product development director at Leidos, Reston, Virginia. “Just as trucks can be scanned at border crossings, customs agencies can deploy the same cargo inspection technologies to scan containers at ports of entry and rail border crossings. By ensuring cargo inspection is in place at all entry/exit points, officials can control the import or export of shipping containers, detect hidden contraband and verify the crossing of legitimate trade items.”

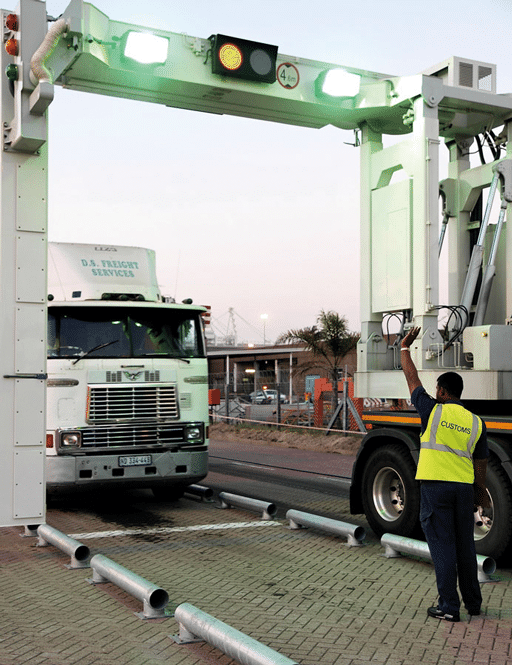

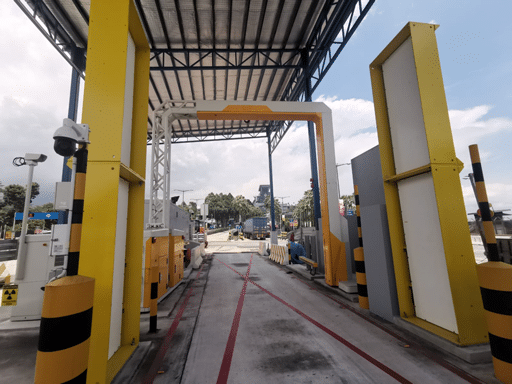

Utilizing non-intrusive inspection (NII) large-scale X-ray and gamma-ray machines for cargo screening help process this cargo and ensure that only legally allowed material travels in and out. These systems can scrutinize entire trucks and multimodal containers using imaging and composition information to enable operators to find contraband without unloading it. Containers are screened as early in the supply chain as possible and done rapidly without slowing down the movement of trade. CBP’s 61 operational CSI ports (in North America, Europe, Asia, Africa, the Middle East, and Latin and Central America) now prescreen over 80 percent of all maritime containerized cargo imported into the United States.

The process is similar to the imaging that carry-on baggage undergoes at airport security stations. CBP personnel may open some containers and examine their contents by hand if the images suggest that the cargo is potentially dangerous or deviates from the contents stated in the manifest.

Nonintrusive Imaging

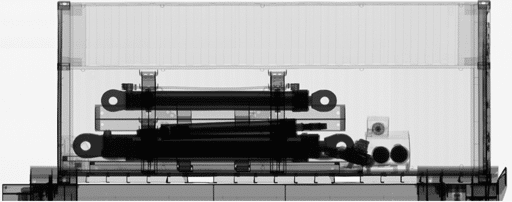

Containers that the Automated Targeting System (ATS) flags as having a risk above a certain threshold undergo nonintrusive imaging, which gives CBP officers a way to see inside a container without the time-consuming and labor-intensive process of unpacking it. Nonintrusive imaging machines use either X-rays or gamma rays to penetrate the container and create an image of the contents. CBP operators are trained to identify suspicious cargo and discrepancies between what they see in the container and what the manifest in ATS describes. For example, the machines can detect dense nuclear materials or shielding, much as an X-ray can show the location of shrapnel in a wound.

The containers flagged for nonintrusive imaging are removed from the ship and placed along the pier or taken to another fixed location. When an imaging machine becomes available and arrives at the pier, CBP officers use it to inspect the containers. Imaging a container takes only a few minutes (compared with hours to unpack and repack it), although containers can be delayed for a few hours while they await imaging. Nevertheless, imaging disrupts the flow of incoming containers much less than unpacking, and imaging requires fewer people.

Gamma-ray radiography technology is a type of cargo scanner that uses gamma rays to create images and 3-D mappings of content location, as well as other important information. It is one of the most common types of scanners and is used for both air cargo and maritime cargo. Gamma-ray systems use a reliable isotopic source and are relatively easy to use, and most have small radiation exclusion zones. Some systems can also determine certain types of material inside the container based on atomic characteristics; a few of these detectable materials are carbon, nitrogen, oxygen, silicon, chlorine, aluminum and iron. Gamma-ray systems can scan standard 40-foot containers in a few seconds and generate a total inspection time of less than a minute. These systems are available in mobile, portal, gantry and fixed-site deployment configurations. Current vehicle pass-through speeds in fixed-site systems (where the inspection unit is stationary) are approximately four to five miles per hour and some systems could attain speeds of more than 10 miles per hour in the future.

Used for both air cargo and maritime cargo, X-rays are a type of electromagnetic radiation that transmits as waves. Today’s high-energy X-ray systems have linear accelerator sources that can penetrate dense cargo, detect differences in material densities and produce quality images for successful contraband detection. Operators will visually — sometimes with the help of sophisticated software — inspect the X-ray images for anomalies. X-ray systems generally take a few minutes to scan a standard 40-foot container while some more advanced systems can take only a few seconds. However, total inspection cycle times may range from 7-15 minutes or longer due to image analysis.

AS&E images.

Guillebaud explains there are still legacy gamma-ray scanning systems in use, but X-ray-based scanning systems have become more prevalent due to advancements in technology, improved safety measures, and the ability to avoid deployment of radiation sources. “Additionally, regulatory and safety concerns have influenced the shift away from gamma-ray scanning in most countries.”

Neutron inspection systems can automatically detect the presence of specific threat materials, such as explosives and drugs. Fast neutron techniques are attractive for these applications as neutrons have the required penetration, interact with matter in a manner complementary to X-rays and can be used to determine elemental composition.

The Technology

While there have been incremental advancements in imaging technology, Guillebaud explains the most valuable innovations in cargo inspection have been the automation of image analysis and threat detection using artificial intelligence/machine learning (AI/ML) technology. “The convergence of operationally resilient and cybersecure enterprise software platforms are beginning to accelerate and force-multiply customs operations. As a strategic focus area for Leidos, we are working with customs agencies to provide remote screening with AI-assisted analysis algorithms for threat detection and manifest verification in operational environments. These two technologies will allow customs agencies to centralize and leverage their scan data, correlate scans with other internal data sources, apply AI assistance at scale, and deliver that information anywhere within their organization for smarter, data-driven enforcement.”

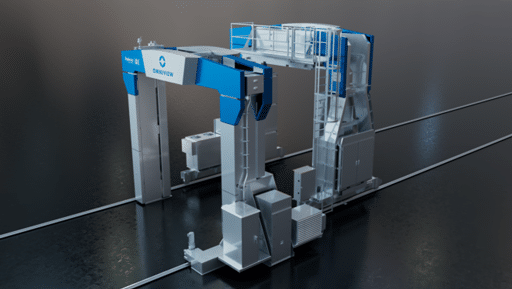

Billerica, Mass.-based American Science and Engineering Inc. (AS&E) has a OmniView ZBx Gantry system that provides detection capability by combining high-penetration transmission imaging with photo-like Z Backscatter imaging. The system provides multi-view and multi-technology imaging of trucks, cargo containers, and tankers. The system features penetration of 430 mm of steel and captures Z Backscatter images from three views for left-, right-, and top-side imaging of cargo. This combination of technologies provides imaging for successful manifest verification and detection of threats and contraband.

AS&E’s Rapiscan Eagle G60 Series is designed to operate with a small staff. This makes this system ideal for cargo control inputs of sensitive sites, border crossings and also to seaports. These units can be quickly disassembled and shipped to another site, requiring only the laying of rails on the new site. Available with a 6 MV linear accelerator, it is capable of providing a penetration of 400 mm with an optional dual energy source. The source and the X -ray detectors are placed in an electric gantry conveyor mounted on rails. The system automatically scans unoccupied vehicles on rails while the gantry moves over them. Rail length determines the number of vehicles that may be inspected by a single passage. The gantry is controlled remotely from a control room where the X-ray images are sent for analysis and evaluation. The multiple levels of imaging performance create flexibility for customers to select the system configuration ideally suited for their unique requirements.

City of Industry, Calif.-based Astrophysics’ HXP-FreightScan is a high-energy portal designed for screening trucks and shipping containers at seaports, border crossings and cargo centers. The portal is fully automated and can process up to 160 trucks an hour. Its precision software allows drivers to remain in their vehicles during screening and with a tunnel height of five meters (16.4 ft.), even oversized cargo can be scanned. The system is powered by a powerful betatron generator capable of penetrating up to 12.6 inches of steel. Its clear, high-resolution images make it easy for operators to identify threats and verify manifests, while its rugged construction ensures cost-effective operation.

Designed as a freight screening solution for air cargo, Reston, Va.-based Leidos’ PX 18.18 200 can also be used in other environments such as seaports, warehouses, manufacturing centers and military bases. The system can reduce the need to unpack contents for inspection, accelerating screening of consolidated cargo in skids and pallets while maintaining a high level of security. It offers a single-view, compact inspection system with penetration and image quality ensured by Leidos’ 200 kV X-ray source. The system is configurable, allowing customers to choose either a dual-view configuration or a single-view system that later can be upgraded in the field. The PX 18.18 200 includes a heavy-duty conveyor with narrow pitch rollers designed to facilitate loading and unloading of pallets via forklift.

The Shenzhen, China-based Safeagle’s large-scale model F150180C X-ray baggage screening system has tunnel dimensions designed to meet the requirements and applications of forwarders, warehouses and couriers for airport and seaport, allowing to detect various palletized cargos. Supported by the Dual Energy Imaging Detection System (DEIDS) with more than 20 imaging processing tools, operators can identify materials and view screened objects in four colors. The dual-energy imaging displayed is in different color-coding of materials with different atomic numbers, so that operators can easily distinguish the contraband from other items.

Acton, Australia-based CSIRO’s air cargo scanner uses a scanning technique combining high-energy neutrons with X-rays or gamma rays to produce images that show not just the shapes but also the composition of cargo items. The CSIRO scanner collects two separate radiographic images, one using X-rays or gamma rays and one using fast, high-energy neutrons. In contrast to X-rays which are stopped by dense materials such as metals, neutrons are most readily blocked by organic materials and substances with high hydrogen content. This means that by combining the X-ray and neutron images it is possible to construct a composite image that shows items colored according to their composition. The technology is easily integrated with existing airport systems and is non-intrusive to minimize the impact of security measures on rapid freight movement. Pallets and unit load devices can be scanned without being unpacked, allowing high volumes of cargo to be rapidly screened.

As trade volumes increase, Guillebaud explains the demand on speed and quality of cargo inspection is driving the need for AI-based algorithms to assist border authorities in processing larger volumes of cargo while maintaining the quality of inspections. “AI-assisted analysis accelerates the customs clearance workflow by identifying anomalous items in cases where the human eye cannot.”