Cargo security keeps goods safe. On freighters, docks, trucks, railcars, warehouses, and ports, cargo shipments are vulnerable to theft during several stages of the transit process. If a container isn’t properly and securely sealed, it can be opened many times during transit with its contents stolen and easily sold on the black market.

Stolen cargo can cost suppliers thousands to upwards of millions of dollars. An estimated $223 million in cargo was stolen during 2022, according to a new analysis by Verisk’s CargoNet. CargoNet recorded 1,778 supply chain risk events in the U.S. and Canada in 2022, a 15% increase from 2021. The average value of cargo stolen in an event was $214,104, CargoNet said.

The consequences of not sufficiently protecting cargo can be devastating, ranging from financial loss and damaged reputation to long-term, intricate legal disputes. And, today’s thieves are now highly tech-savvy and constantly developing modern ways and strategies to steal cargo from shippers. Because of this, more advanced container security measures have been developed helping to reduce burglaries and resulting theft claims.

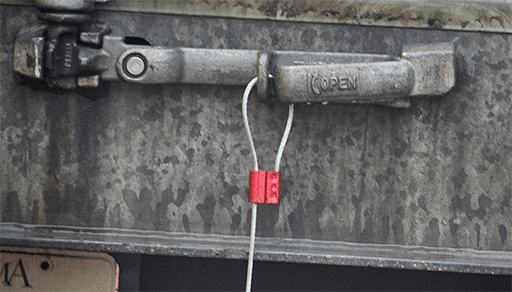

J. J. Keller image.

Best Practices

Josh Lovan, industry business advisor at J. J. Keller & Associates, Inc., Fort Smith, Arkansas, explains that ensuring cargo security during transit is crucial and cites the following best practices to make this happen:

• Use High-Quality Seals: Invest in security seals made of durable materials like metal or heavy-duty plastic. Avoid using seals that can be easily tampered with or broken.

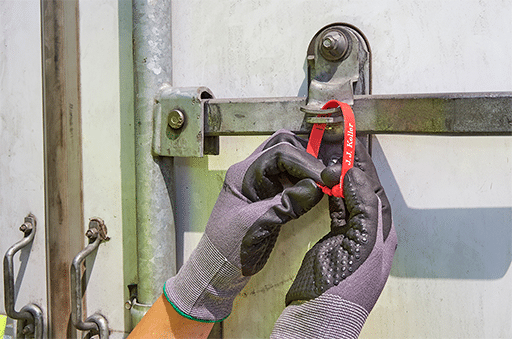

• Proper Application: Apply seals correctly, ensuring they are securely fastened to prevent tampering or unauthorized access.

• Unique Identification: Use seals with unique serial numbers or barcodes for easy tracking and identification. This helps in verifying the integrity of the cargo.

• Regular Inspections: Conduct routine inspections of seals and locks throughout the transit process to detect any signs of tampering or damage.

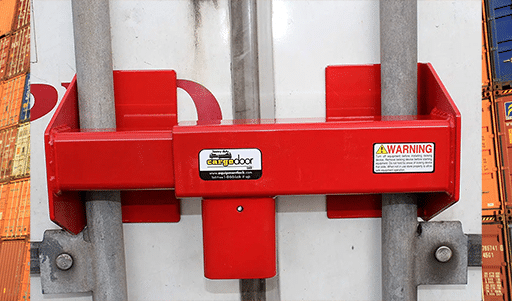

• Multiple Layers of Security: Utilize multiple layers of security, such as container locks in addition to seals, to provide added protection against theft or unauthorized access.

• Security Protocols: Implement strict security protocols and procedures for handling, loading, and unloading cargo to minimize the risk of tampering or theft.

• Monitoring and Tracking: Employ GPS tracking systems or other monitoring technologies to track the location and status of cargo in real-time, providing visibility throughout transit.

• Training and Awareness: Train personnel involved in handling cargo on security protocols and the importance of maintaining the integrity of seals and locks.

J. J. Keller images.

Seals and Locks

Security seals and container locks are requisite to keep cargo secure in transit. Not all seals and locks are created equally. Each type of seal or lock offers different levels of security and suitability for specific applications.

Different industries employ a variety of security seals tailored to their specific needs and cargo requirements. For instance, the transportation industry relies on heavy-duty seals like bolt seals or cable seals to secure shipping containers and trailers, safeguarding valuable goods during transportation. Industries dealing with retail and consumer goods prioritize tamper-evident seals with unique identification features to maintain the integrity of products as they move from manufacturers to retailers.

“Pharmaceutical and healthcare companies often opt for advanced seals equipped with RFID technology, enabling real-time tracking and monitoring of sensitive pharmaceutical products to comply with stringent regulatory requirements and maintain product integrity,” Lovan says. “The food and beverage industry may utilize seals designed to withstand environmental factors and provide clear evidence of tampering, ensuring food safety and compliance with regulatory standards.”

It’s essential to assess your cargo security requirements and choose the appropriate seals and locks accordingly. Overall, Lovan believes the choice of security seals varies across industries based on factors such as cargo value, sensitivity, transportation mode, and regulatory compliance needs, with each industry selecting seals that best meet their unique security requirements. He cites the following types of security seals and container locks available for cargo security.

• Bolt Seals: These are high-security seals that require bolt cutters to remove, making them difficult to tamper with.

• Cable Seals: Made of steel cables, these seals are flexible and suitable for securing irregularly shaped items. They offer high tensile strength and are resistant to tampering.

• Bar Seals: These seals feature a metal bar that is inserted into a locking mechanism, providing a secure closure for containers and trailers.

• Plastic Seals: These seals are commonly used for securing shipping containers, trucks and trailers. They are lightweight, cost-effective, and offer tamper-evident features.

• RFID Seals: These seals are equipped with radio frequency identification (RFID) technology, allowing for electronic tracking and monitoring of cargo in real-time.

• Kingpin Locks: These locks are installed on the kingpin of a trailer, preventing unauthorized access to the container when it is attached to a truck.

• Wheel Locks: These locks are placed on the wheels of trailers or containers to prevent them from being moved or accessed without authorization.

Below are criteria for determining the best seal for your application:

• Determine if an indicative or barrier seal is required.

• If using a barrier seal, determine what strength level is needed.

• Make sure that the seal type that you choose fits the device.

• Choose a seal that has the appropriate level of strength and security.

• Measure seal cost vs. security risks.

• Use a manageable locking system considering the tools and resources you have at your disposal.

• Consider the durability of the seal in relation to its environment.

• Below are criteria for handling and use of cargo seals:

• Know the locking procedure, design and features of this seal.

• Give seals only to authorized persons.

• Document all seals taken from storage.

• Apply seals securely according to instructions for this model. Note any problems or unusual visible damage like bent hasps, worn holes, unusual conditions or cosmetic damage to seals in applying.

• Destroy seals completely after use. Do not simply toss them out or leave parts or cut seals intact; or under conditions where they may be collected by others. Ideally it is good practice to return them to a central facility for destruction by an authorized and trained inspector.

Reliable Line of Defense

While these locks and seals are a reliable line of defense, criminals can compromise security seals and container locks through various methods such as brute force, and tools like bolt cutters to break seals or manipulate locks. They also employ tampering techniques, like duplicating seals or picking locks, to gain unauthorized access to cargo.

C-TPAT stands for Customs-Trade Partnership Against Terrorism. Founded shortly after the terrorist attacks of September 11, 2001, C-TPAT is a voluntary, collaborative effort between U.S. Customs and Border Protection (CPB) and commercial shippers to develop comprehensive cargo security programs for imports into the U.S. To further prevent theft, C-TPAT seals are security seals affixed to cargo containers by C-TPAT certified entities, signifying compliance with rigorous security standards. These seals serve as an indicator of a secure supply chain, facilitating expedited customs clearance and reducing the risk of cargo tampering or terrorism-related threats. C-TPAT seals may feature unique identification numbers or barcodes, allowing for easy tracking and verification of cargo integrity.

GPS Tracking

With numerous companies and transportation methods involved throughout the transportation chain, pinpointing when and where a cargo security issue occurred can be daunting. Implementing a GPS tracking solution on cargo shipments provides suppliers with the ability to track their cargo throughout the entire journey, adding invaluable insight and security.

“With so many transportation methods and entities involved, cargo can be lost or delayed along the way,” says Jeff Karg, director of marketing and communications, PassTime, Littleton, Colo. GPS tracking devices for cargo shipments give the supplier their own tracking solution and are not reliant on the varying and sometimes non-exist tracking solutions from their transportation providers.”

Solutions like PassTime’s battery-powered Encore, are completely self-powered, can last up to five years without recharging, and at the size of a deck of cards, can quickly and easily be placed on just about any cargo shipment.

“Utilizing battery-powered GPS tracking solutions on the cargo itself means suppliers know if their cargo is still in transit, or more importantly, if it isn’t,” Karg says. “Locks and seals are an important aspect of cargo security. However, if the cargo container itself is lost those safeguards may have limited impact. Adding an additional layer of security, like a GPS tracking solution, can provide unparalleled visibility, control and protection to locate and recover missing cargo.”

Smart Containers

Smart containers are equipped with sensors that can detect intrusions like unauthorized door openings as well as anomalies such as a sudden change in container pressure or temperature (like when a hole is cut into the side wall of a container) that could indicate a breach.

Smart containers also have other integrated sensors such as GPS as well as additional internal sensors to measure the condition of the cargo inside. Data from the container’s sensors are either logged on a data module within the container, or it’s broadcast to a central monitoring platform via handheld readers, fixed scanners, or GSM/cellular connections.

Another, probably more viable option to (expensive) smart containers is the use of portable smart sensor kits that can be fixed to/within any standard container or truck trailer. These “smart kits” can turn any shipping container, truck trailer, or rail car into a “smart container,” giving logistics operations greater supply chain visibility for high-value cargo like pharmaceuticals, volatile chemicals, frozen food and other cold chain products.

The Human Element

Most theft crimes are not investigated because of manpower issues, so it is imperative that carriers take the necessary measures to prevent theft. Provide security training to all personnel, because everyone should be involved with protecting customer freight and company assets. Lovan says drivers can proactively deter theft by adopting the following prevention measures:

• Check the cargo seal and padlock during pre-trip and after being away from the unit.

• Never leave the tractor running when unattended.

• Always lock the doors and roll up windows when away from tractor.

• Always park in well-lit areas where other motorists are present.

Fleets can deter theft by implementing the following security polices during closed hours:

• Ensure trailers are docked, butted, and blocked at the terminal.

• Utilize kingpin locks for trailers that contain high value freight.

• Ensure that alarm systems are functional by conducting weekly tests.

• Utilize GPS technology to geofence equipment on the yard.

While no cargo being transported is completely immune to the risk of theft, the right technology will help to mitigate these problems to a great extent and help to ensure safe transportation of cargo. Anticipate and use security developments to your advantage, stay one step ahead and keep your cargo secure.