Whether in small parcels in air cargo, or large containers on ships, trains, and trucks, smugglers are always trying to find new ways to evade detection. “It’s a chicken and egg situation,” said aviation security consultant Steve Wolff, president of Wolff Consulting Services. “Smugglers will try something and then, when they get found out, they’ll try something else.”

As a result, the range of items that need to be detected by cargo screening technology is wide and varied. “The common threats faced include explosives, weapons, narcotics, contraband, undeclared or misrepresented goods, currency, agricultural items, cultural artifacts, items presenting environmental risks, counterfeit goods, and weapons of mass destruction,” said Huayu Li, assistant president and general manager of international civil aviation with the security scanning technology company Nuctech.

When it comes to smuggling via large containers, the usual motive is profit, which is why the emphasis in screening ls is on the detection of illegal and banned goods. The same criminal motive plays a role in air cargo smuggling, but it is often accompanied by a desire to inspire terror through acts of mass destruction. “This is why the most common threats confronted by air cargo screening are explosives in their different forms,” said Harald Jentsch, head of Airports & Baggage Screening and interim head of Air Cargo Screening for Smiths Detection, a global leader in threat detection and screening technologies. “Beyond that, other contraband and dangerous/prohibited items like narcotics, currency, fireworks, and bio-threats are being met with increasing demand.”

Smiths Detection

Balancing Security and Speed

In a perfect world where time and money didn’t matter, it would be possible to painstakingly screen every piece of air, land and sea cargo using human-based examinations and searches. But we live in the real world where time and money do matter. So, to screen cargo in an economically viable manner, cargo inspections must be done in a timely yet thorough manner.

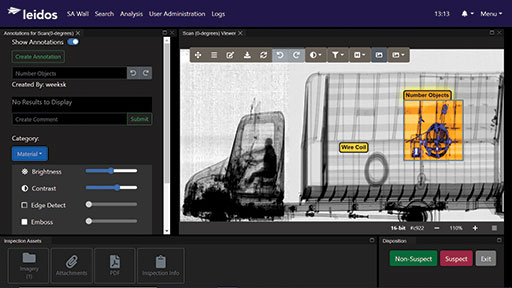

“Customs and border control agencies are always challenged to balance national security and economic interests,” said Mathieu Guillebaud, product development director with Leidos, a global provider of enterprise security technologies and solutions. “The facilitation of legitimate trade and travel are essential, but they also need to rapidly assess the legitimacy of cargo and travelers.”

Leidos

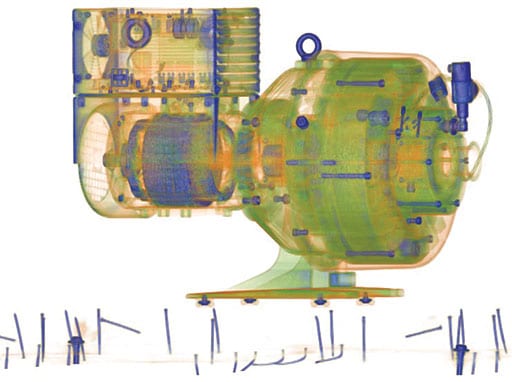

This is why security personnel rely on 2D x-ray scanners and their 3D Computer Tomography cousins (aka CT, which employs a combination of x-ray scans from different angles and image processing by sophisticated scanning algorithms) to speed up the process while ensuring its thoroughness and accuracy. And because goods are moved using all shapes and sizes of containment, these scanners ran the gamut from small conveyor-belt type systems for air cargo to large drive-through rigs for trucks, trains, and seaborne shipping containers.

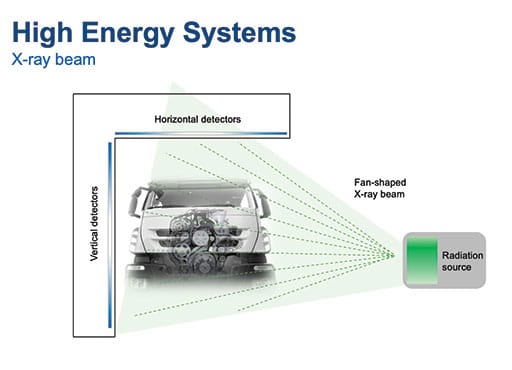

“When it comes to x-ray/CT systems we can split them into two big categories,” noted Sara Bracceschi, head of Consulting and Services for Customs at the Center for Adaptive Security Research and Applications (CASRA). “There are the low energy conventional systems that are used at airports for mail screening, baggage and air cargo. And then we have the high energy x-ray/CT systems that are used for shipping containers and vehicles such as cars, trucks, and trains.”

Whatever the cargo scanning system, vendors of this equipment are constantly making improvements and advances to keep up with smugglers, and get a step ahead of them whenever they can. Here are some of the technology trends that are making this possible.

Adopting Baggage Innovations

In the wake of 9/11, the terrorist security risks associated with air passenger travel have driven this sector to the forefront of automated, technology-based screening. But now everyone else is catching up: “Air cargo is starting to implement all the advances in technology that we’ve seen in airports,” said CASRA’s Bracceschi. “So 3D CT scanners for baggage, for mail, and the like are finding their way through to air cargo.”

CASRA

As for ground cargo? “The bigger the object that has to go through the screening tunnel, the bigger the machine to scan it,” she said. Here too, advances in x-ray scanning equipment have made their way to the cargo market. “The original high energy system would only provide one view of the vehicle,” Bracceschi explained. “But now we have dual view systems, and sometimes these views can be combined with top and bottom views as well. In addition to x-ray systems that focus on penetration, security screeners are using ‘backscatter’ x-ray systems that can reveal details inside containers based on the dispersion of x-rays, which allow lower doses to be used.”

Getting More Out of CT

When it comes to scanning large cargo at the airport, size is an issue; specifically, “the size of the rotating slip ring in the CT,” said Nuctech’s Li. Cargo that is too big to be scanned within the CT’s rotating slip ring “needs to be manually separated, screened and repacked before it can be allowed through, which consumes a lot of manpower, time and valuable space at the airport.”

In order to solve the above problems, Nuctech has developed a new generation of static CT scanners that don’t require rotating slip rings to do their jobs. The three new models are the WooKong H, WooKong L, and CTitan.

“CTitan is the world’s largest CT security inspection equipment capable of scanning ULD (unit load device) or pallet-consolidated cargo as whole items,” Li said. “With a high-energy X-ray source, CTitan can scan ULD or palletized cargo up to 4.73m long and 3m high, capable of displaying a full 3D images of the entire ULD and detecting explosives automatically.”

IDSS

Taking A Different Angle

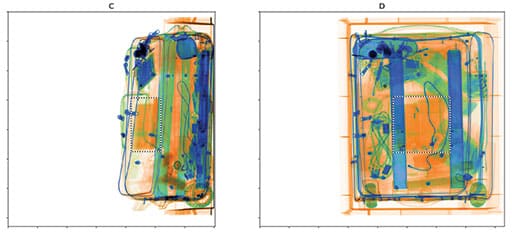

Pallets/skids are a very common way to ship cargo, and one that can confound security screeners who need to do thorough checks while keeping goods moving though their facilities. To solve this problem, Integrated Defense and Security Solutions (IDSS) is developing the IDSS DETECT CS320 Scanner, with partial funding coming from the US Department of Homeland Security (DHS) Science and Technology Directorate (S&T).

What makes the CS320 different is that it is designed to scan entire pallets from a horizontal position. “This solution thus reduces the footprint required of a typical X-ray or pseudo CT scanner that requires a skid to pass through the X-ray field,” said IDSS President and CEO Jeffrey Hamel. “As such, it will eliminate the need for break bulk scanning and significantly improve throughput in a 100% screening environment.”

While reducing the space and time required to screen pallets, the CS320 will provide high resolution fully rotatable 3-D images to operators “with the most comprehensive non-intrusive inspection tools to quickly identify explosives, and weapons hidden within full-sized packaged cargo pallets or skids without breaking them down,” said an IDSS news release. “The Artificial Intelligence (AI) detection algorithms will be enhanced to provide automated detection of potential threats and items of interest.”

Going Handheld

For years, the sheer size and weight of x-ray/CT scanning systems have been limiting factors in their use in tight and/or spread-out locations. But things are changing: “Some vendors have developed small backscatter x-ray devices that are portable,” Wolff said. “These units are small enough that you can pick them up with two hands, walk to a container, and then place the device against the container wall to see what’s inside.”

Multi-Energy Portals

Torn between deploying low portal scanning systems that won’t hurt humans or high-power systems that can see what’s inside steel-walled containers? Then why not do both? In today’s multi-threat, time-sensitive screening environment, “flexible, multi-energy portals (MEP) are vital for automating the commercial cargo inspection process for customs and border control agents,” said Leidos’ Guillebaud. “These systems provide a low energy scan for the passenger cab and higher penetrating X-ray dose for the container or trailer. With automation, MEPs help ensure all cargo is efficiently screened while maintaining a high throughput rate at inspection checkpoints.”

Not surprisingly, Leidos offers a MEP solution for these kinds of situations. “The Leidos VACIS IP6500 MEP was the first of its kind and has been deployed by the U.S. Customs and Border Protection,” Guillebaud said. Better yet, the Leidos system also accesses driver immigration information and truck manifest automatically using RFID and/or QR code technology. “As this information is combined into a single integrated data package, officers can adjudicate the cargo or conveyance without the driver exiting the cab,” he noted.

Doing the Neutron Dance

Forget the Pointer Sisters: In those situations where x-rays/CTs have a difficult time penetrating truly dense materials, neutron-emitting scanning systems can provide security screeners with the ‘in-sights’ they need to detect dangerous materials and contraband.

“If someone’s shipping a whole bunch of engine blocks, it’s very hard for the x-ray machines to penetrate, to see what’s actually inside those blocks,” said Wolff. “But neutrons can penetrate dense objects very easily. Where they tend to fall down is in the very light stuff, but this is an area where x-rays excel; making the two technologies complementary to each other.”

“There’s other things you can do with neutrons as well,” he added. “For example, you can use neutrons to do elemental spectroscopy. This allows you to look at the elemental composition of items inside the container.” This is a faster alternative to breaking open boxes and/or running dogs around the containers during secondary searches, after primary searches point to something suspicious.

Getting More From The Data

Today’s modern CT scanning systems rely on image-processing algorithms to translate the raw x-ray data into viewable, intelligible images. “Companies such as Smiths Detection are constantly improving algorithms for the automatic detection of dangerous goods, prohibited items, currencies, wildlife, and counterfeit products,” said Jentsch. “Advancements such as iCMORE (the company’s latest generation of detection algorithms) will only continue to advance the specificity of screening.”

In addition to enhancing its image-processing algorithms, Smiths Detection is doing what it can to improve overall image quality and resolution, as well as making its user interface more intuitive. The company’s goal is to speed up the air cargo screening process without compromising security.

That’s not all: “Increased networking capabilities, the advancement of data-analytics, connectivity, and operational management will deliver strong operational advantages for air cargo operators,” Jentsch said. One such advance is the adoption of Open Architecture (OA) software, which enables the interoperability and interfacing of security screening algorithms, and screening hardware from different suppliers within one solution. “OA is progressing to gain acceptance once regulatory requirements are fulfilled,” he noted.

Bring On The AI

With its ability to crunch massive amounts of data quickly and derive useful analyses from these efforts, artificial intelligence (AI) is proving to be a very useful tool for automated cargo screening

A case in point: “Cybersecure and operationally resilient software platforms – with AI-based analysis algorithms for threat detection — are beginning to accelerate and force-multiply customs operations,” said Leidos’ Guillebaud. “Leidos’ enterprise software platforms utilize these capabilities to enable customs agencies to centralize and leverage their scan data. They can also correlate scans with other internal data sources, apply AI assistance at scale, and deliver that information securely within their organization or with other trusted organizations. Furthermore, these innovations support remote analysis and manifest verification in operational environments.”

Nuctech sees similar benefits from harnessing AI to automated cargo screening. “When it comes to image and dangerous goods recognition, AI technology can provide a great deal of help,” Li said. For instance, AI can reduce the impact of human error by avoiding omissions and security vulnerabilities caused by security personnel fatigue, bribery and other factors. It can also improve screening efficiency because an AI’s computing speed is much faster than the human brain, and AI can perform a vast number of repetitive tasks accurately without the need to rest; reducing labor costs in the process.

AI is not a ‘magic bullet’. “Although AI recognition is developing rapidly, the role of human beings cannot be completely replaced, because complex and/or unknown situations still need to be manually handled,” said Li. “In addition, when it comes to safety issues, the conclusions drawn by an AI-enabled screening system still needs to be judged by a human security inspector.”

“AI is not a panacea,” Wolff agreed. “It works best when you have a controlled population and you’re trying to figure out something within that population, like doing facial recognition for a company like Amazon. You collect facial data on the entire population of Amazon, and then apply AI as a security screening device. In this context, it works very well.”

Where AI starts “falling down” is in uncontrolled situations, he continued. “If something comes in that’s not in the data set, the computer reacts in unfamiliar ways. I call it ‘computer panic’: The AI-enabled computer doesn’t know what to do because it has not seen that test case before. So, it kind of panics and throws out something that’s quite often very, very strange.”

More Innovation Is Coming

Although the many advances made in cargo screening to date have made the process faster, reliable, and able to handle large volumes of shipments, the quest to perfect this technology is unceasing. This is why the future development goals of cargo security inspection is to continually improve the safety levels and the speed of security clearance, while reducing the use of human operators in the system.

“For instance, CT equipment is already the highest level of security equipment for cargo scanning in the industry, so the future may be improved by the combination of CT and other security inspection technologies,” concluded Li. “There is also plenty of room to improve AI recognition functions, including the accuracy of AI recognition and expansion of the recognition range.”