Alexander MacDonald, 30, of Chelmsford, England, a passenger who yelled and became physically aggressive on a United Airlines flight from London to Newark caused the crew to divert to Bangor, Maine in March. United Airlines Flight 883, left Heathrow Airport near London on March 1 and headed to Newark Liberty International Airport in New Jersey. Several hours into the flight the lead flight attendant heard loud arguing and asked the man to lower his voice, according to an affidavit. He agreed, but minutes later he was yelling again, this time at another flight attendant, the affidavit says. The cabin crew tried to calm MacDonald down but he “would not listen and continued to be verbally and physically aggressive,” according to the affidavit. MacDonald threatened to “mess up the plane,” the affidavit states. He also put his hands on the purser’s shoulders and backed the purser into a corner, the document says. Crew and passengers restrained him in flexible handcuffs. He “continued to be noncompliant” and the flight was diverted. MacDonald has been ordered to pay the airline $20,638 in restitution, according to federal prosecutors. He was sentenced April 25 to time already served, prosecutors said. He had been in custody since March 1, when he was arrested after the flight landed at Bangor International Airport. He pleaded guilty on March 22 to one count of interfering with a flight crew, a felony punishable by up to 20 years in prison.

Category: Aviation

TSA Announces the Publication of the Flight Training Security Program Final Rule

The Transportation Security Administration (TSA) published in the Federal Register a final rule for the Flight Training Security Program. The final rule updates the Program to improve its efficiency and effectiveness, including the security threat assessment process for flight training students. The final rule will take effect on July 30, 2024.

Until the regulation takes effect, all requirements and existing processes remain as is stated in the current regulations (49 CFR part 1552) and on the program portal.

The Flight Training Security Program, which has been in effect since at the Department of Homeland Security and TSA since 2004, covers flight training providers, including individual Certified Flight Instructors, who provide training to all flight students, with the exception of foreign military pilots training in the United States through a Department of Defense endorsement and in accordance with the U.S. International Military Education and Training Program. All non-citizen flight trainees are subject to a Security Threat Assessment, which is a TSA background check conducted on all databases relevant to confirming an individual’s identity, that the individual possesses lawful status in the United States, and that the individual does not pose a security threat.

Currently, prospective trainees must submit an application and pay a fee for each training they wish to attend. The final rule is time-based. After undergoing vetting, an applicant who receives a positive determination of eligibility will receive a Certificate of Eligibility, pay a one-time fee and can train as often as desired within a five-year period as long as they remain eligible. During that period, TSA will conduct recurrent vetting to ensure no new information emerges that would affect eligibility to receive flight training.

This change improves administration and efficiency for flight training candidates and providers. It has been made possible in part by technology improvements made to the FBI’s record of arrest and prosecution background program used by TSA as a vetting tool. TSA expects the final rule to reduce delays, improve tracking candidate training events, and support the portability of a candidate’s security threat awareness between providers. Providers will no longer pay for multiple event-based training security threat assessments.

The final rule more clearly defines which flight training events require notification and recordkeeping and focuses on the notification of flight training events that “substantially enhance a pilot’s skills,” eliminating numbered training categories previously used.

The final rule is intended to maintain the appropriate level of security, comply with all statutory mandates and improve efficiency for the flight training industry. TSA believes these enhancements may improve access and opportunities for fully vetted non-U.S. citizens and non-U.S. nationals to participate in flight training in the United States and with FAA-certificated flight training providers abroad.

For more information about the changes, read the updated Flight School Training Program regulation in the Federal Register.

Jennifer Aument Appointed CEO of The New Terminal One at JFK Airport

The New Terminal One at New York John F. Kennedy International Airport today announced Jennifer Aument as its incoming CEO, set to assume the role on April 1, 2024. The New Terminal One is currently under construction with its first gates scheduled to open in 2026, in partnership with the Port Authority of New York & New Jersey, as part of the agency’s $19 billion transformation of JFK Airport.

Aument brings over 25 years of experience in developing major infrastructure across the highway, rail, airport, and port sectors. Her career includes executive roles in public-private partnerships and megaprojects, with a focus on safe and efficient project delivery, business performance, community engagement and customer experience. As the president and CEO of Transurban’s North American business for many years, she led the development and expansion of significant public-private infrastructure projects. Additionally, her decade-long tenure as a commissioner for the Virginia Port Authority gave her extensive insights into port operations and development. Earlier in her career, she played a key role in the development of the largest-ever extension of the Washington DC Metrorail for Bechtel.

Most recently, Aument served as chief executive of AECOM’s global transportation business, where she led a team of more than 14,000 to deliver innovative transportation solutions for clients of the industry’s preeminent transportation consulting and design firm. Previously, she spearheaded Transurban’s North American development, construction and operations as president and CEO, contributed to various publicly listed and private boards in the transportation and technology sectors, and shared her knowledge as a lecturer at Cornell University.

“I am excited to soon begin my role with the New Terminal One team and build upon the exceptional foundation that has been laid here,” said Aument. “Significant progress has positioned us well, and I look forward to working with the Port Authority and our partners in the community to set a new global standard for customer experience. My passion for infrastructure drives me and there is no better example than the New Terminal One of the transformative power of infrastructure on communities and economies. I’m thrilled to contribute to its legacy.”

She takes the helm from Dr. Gerrard Bushell, the current CEO. Dr. Bushell led The New Terminal One to lease and financial close amidst a global pandemic that disrupted air travel. He also executed on key partnerships, construction, and operational milestones and agreements; including a path-breaking Project Labor Agreement and alternative dispute resolution agreement with the Building Trades, a $3.9 billion guaranteed maximum price for the Phase A design and construction with AECOM Tishman and Gensler, strong community engagement supporting local workforce participation, and the successful delivery of nearly $800 million in awards for minority and women-owned businesses, as well as the purchase of more than 85% of the project’s trade packages. More recently, he oversaw the successful issuance of $2 billion in green bonds for the project in December 2023 to support the scheduled delivery of the project for 2026.

“We thank Gerrard for his many contributions over the years, making this project the success that it is today,” said Luke Bugeja, chairman of the board of directors of JFK NTO LLC and CEO of Ferrovial Airports. “We look forward to welcoming Jennifer to the New Terminal One team. Her dedication and passion for this industry will now bring her global vision, market insight, and energy to lead in delivering this world-class terminal to New York City, committed to local communities and travelers worldwide.”

“Jennifer brings an impressive depth of experience and a proven track record that strongly positions her to lead our project into the next phase,” Dr. Bushell remarked. “I want to express my deep gratitude to our sponsors and our exceptional team, whose commitment to excellence has been unwavering. Leading this project from the start has been both a privilege and an honor, and I’m looking forward to witnessing NTO’s continued success.”

The New Terminal One is backed by a group of industry leaders including Ferrovial, JLC Infrastructure, Ullico and Carlyle, illustrating the enduring pursuit of excellence that defines the project.

Indra Modernizes the Ground Surveillance System at Paris CDG

Indra has been awarded a contract by Direction des Services de la Navigation Aérienne (DSNA), the entity in charge of air traffic control in the French airspace. Indra is modernizing the ground surveillance system (A-SMGCS) at Paris’ Charles de Gaulle airport to ensure reliable operations and minimize delays and cancellations.

“Our current capacity allows for the arrival of 73 flights and departure of 76 flights per hour, but if we are forced to use the fallback system, we can only accommodate 30 arrivals per hour, which would result in cancellations,” said Laurent Giger, head of CDG ATC Systems Department at DSNA. “With the upgrade, however, we can accommodate 48 arrivals even with the fallback system, which may lead to some delays but not cancellations.”

Paris Charles-de-Gaulle is one of the few airports in the world where three aircraft can depart or land simultaneously. The airport is amongst the busiest in the world, with 67 million passengers in 2023. The complexity of four parallel runways, four control towers and 36 operational controller working positions makes it critical for DSNA’s air traffic controllers to have a precise overview of the ground operations.

Many of the world’s largest airports operate with Indra’s InNOVA ground surveillance systems. The InNOVA system retrieves information about all flight and vehicular traffic in the air and on the ground from ground surveillance movement radars (SMRs), MLAT, and other sensors. Indra’s best-in-class tracking technology analyses and processes the data, refining the information, and displays it to operators to include only what truly matters. The process of sifting out unwanted “noise” reduces disturbances caused by false targets, thereby increasing operational efficiency and controllers’ situational awareness — and ultimately improving safety at busy airports. With the upgrade, DSNA’s controllers will benefit from the latest generation of this technology, with advanced tracking, labelling and classification of relevant objects.

DSNA has used Indra’s ground surveillance system since 1997. The modernization comes as Paris is preparing its infrastructure for the Olympic Games and the site acceptance test for the first step was approved in mid-March 2024. DSNA will, by the end of the modernization project, have a state-of-the-art system that is ready to adopt advanced safety functionalities as outlined by the EU in the Common Project 1.

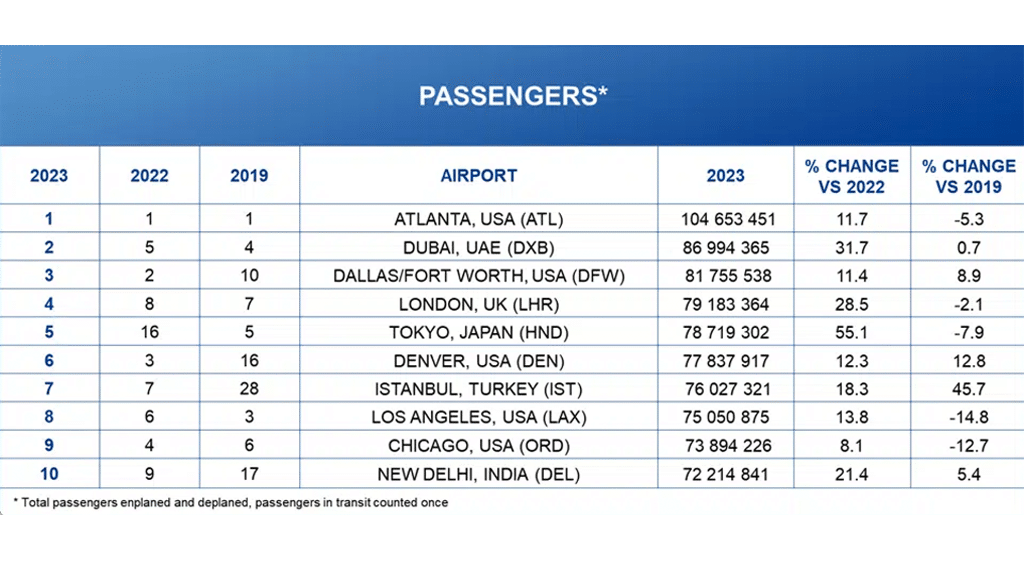

Top 10 Busiest Airports in the World Shift With Rise of International Air Travel Demand

Airports Council International (ACI) World has today unveiled the highly anticipated preliminary top 10 busiest airports worldwide for 2023, showcasing significant shifts driven by the resurgence of international air travel.

The global total passenger forecast for 2023 stands close to 8.5 billion, reflecting a remarkable recovery of 93.8% from pre-pandemic levels. Notably, international traffic recovery drew nearer to that of domestic traffic, emphasizing its essential role in propelling the industry’s resurgence and expansion.

The influx of passengers at international airports has been central in bolstering the recovery of hubs reliant on this segment, consequently influencing the composition of the top 10 busiest airports for total passengers.

ACI World director general Luis Felipe de Oliveira said, “Global air travel in 2023 was chiefly fueled by the international segment, propelled by several factors. Among these were the anticipated benefits from China’s reopening and a growing inclination towards travel despite macroeconomic conditions. While perennial leaders from the U.S. continue to dominate the top 10 busiest airports for passengers, notably Hartsfield-Jackson Atlanta International Airport retaining its number one position, there are notable shifts. Dubai International Airport jumped to second rank for the first time, while Tokyo Haneda International Airport witnessed a remarkable ascent from 16th position in 2022 to 5th in 2023. Additionally, the unwavering strength of Istanbul and New Delhi airports keep them in the top ranks, marking significant progress over 2019.

“Notably, cargo continues to play a key role in world commerce despite the year-over-year decrease. Hong Kong International Airport has maintained the top position, followed by Memphis International Airport and Shanghai Pudong International Airport. Doha International Airport rejoins the top 10, jumping to number 8 with a growth of 6.3% over 2019.

“The rankings highlight the crucial role these transportation hubs play in global connectivity, commerce, and economic development. Airports continue to demonstrate their resilience and adaptability amidst the challenges posed by the ever-evolving landscape of global travel. ACI World remains dedicated to advocating for airports worldwide throughout pivotal stages of policy formulation and to advancing the pursuit of airport excellence.”

Airport rankings are based on data gathered from over 2,600 airports across more than 180 countries and territories globally. This vast data set places ACI World in a distinctive position as the foremost authority on airport travel demand, ensuring the utmost accuracy and reliability in its rankings.

Passenger traffic highlights

Preliminary figures indicate that the 2023 global total passengers’ figure is close to 8.5 billion, representing an increase of 27.2% from 2022 or a recovery of 93.8% from pre-pandemic results (2019).

While the domestic market grew by 20.2% (or a recovery of 96.8% of the 2019 level), the international market drove recovery with a 36.5% growth rate (or 90.4% of the 2019 level).

The top 10 airports representing close to 10% of global traffic (806 million passengers), witnessed a gain of 19.8% from 2022 or a gain of 0.7% vis-à-vis their 2019 results (801 million pax in 2019).

Hartsfield-Jackson Atlanta International Airport holds onto the top rank and is followed by Dubai International Airport for the first time, surpassing Dallas Fort Worth International Airport in third position.

From the top 10 rankings for total passenger traffic, five airports are in the U.S.

The biggest jump in the top 10 rankings is recorded for Tokyo Haneda, leaping from 16th position in 2022 to the 5th spot in 2023.

Hartsfield-Jackson Atlanta International Airport is set to host the 2024 ACI World Customer Experience Summit and Exhibition, from September 23 to 26 in Atlanta, USA.

Airport Body Scanner Trends: A TSI Industry Expert Roundtable

According to a January 12, 2024, news release issued by the U.S. Transportation Security Administration, this agency screened a record 858+ million passengers in 2023. Although the TSA news release doesn’t say it directly, it is reasonable to assume that most or likely all these people were checked using body scanners for concealed weapons and contraband. These screenings prevented 6,737 firearms — 93% of them loaded — from getting into the secure areas of the airports and onboard aircraft.

Clearly, airport body scanners are more important than ever for keeping the world’s airports and airliners safe. This is why knowing the trends driving this technology today and into the future is so important for this in the aviation industry.

To get a handle on these trends, TSI magazine staged a ‘virtual roundtable’ with two experts with major body scanner manufacturers. They are Harald Jentsch, head of Aviation Security Screening for Rohde & Schwarz; and Alevtina Snezhina, deputy head of Adani Systems’ marketing department. Here is what the experts had to tell us.

TSI: How have airport body scanners evolved and improved over the years?

Harald Jentsch: Security scanners have evolved significantly over the last decade, largely driven by advancements in artificial intelligence and machine learning technologies. Previously, checkpoint security screening relied heavily on X-ray scanners for baggage and walk-through metal detectors as well as physical pat-downs for people screening. Limited to the detection of concealed metallic items, it wasn’t possible to detect person-borne concealed explosives, ceramic knives, printed weapons, or contraband.

This changed with the introduction of millimeter wave (mmW) security scanners more than 15 years ago, which detect a far wider range of threats and prohibited items. Another change from legacy body scanners is the physical design of the R&S QPS201 Ultra High-Definition (UHD) body scanner. The system has an open design and is fully electronic — comprised of two solid-state flat panels. This means on-person security screening is no longer confined to a narrow cylindrical scanner and is made more comfortable with an easy hands-down scan pose. Further, the QPS201’s large, open pathway is an accessible path for passengers with disabilities and provides additional egress for emergency evacuation situations.

Alevtina Snezhina: The evolution of airport body scanners has been a fascinating journey marked by technological advancements tailored to address emerging security threats in the realm of aviation.

Initially, aviation security measures were minimal as threats were virtually nonexistent in the 1950s. However, with the rise of terrorist hijackings involving metallic weapons such as guns and knives, passenger screening became imperative.

The response to these threats led to the development of Walk-Through Metal Detectors (WTMD) and Handheld Metal Detectors (HHMD), serving as the primary screening tools for person-borne threats for years. While effective against metallic threats, these detectors proved insufficient against non-metallic threats, highlighted by incidents like the attempted bombing by the “underpants bomber.”

To overcome the limitations of WTMD, exploration into new technologies capable of detecting both metallic and non-metallic threats ensued. Initial trials involved Backscatter X-ray Body Scanners, showing promise in detecting metallic and non-metallic items on a person’s body but were unable to identify internal threats. However, concerns regarding ionizing radiation’s potential health hazards led to their removal from use at Manchester Airport.

Subsequently, investment shifted towards the development of alternative technologies, notably active millimeter wave (mm-wave) scanners. These scanners, currently deployed in airports, offer robust detection capabilities. Nonetheless, as the threat landscape evolves, future advancements will likely be necessary to address new techniques that may evade existing detection methods.

TSI: Why are backscatter x-ray units being replaced by millimeter wave scanners?

Jentsch: Body scanners, utilizing backscatter or transmission X-ray technologies, have been replaced by mmW-based scanners in aviation security screening, and many other use cases due to safety and privacy concerns. Millimeter wave imaging has advanced significantly and delivers safe and accurate people screening and as millimeter waves cannot penetrate skin, scanners like those produced by Rohde & Schwarz pose no health risks to travelers and security operators

Snezhina: The replacement of backscatter X-ray units by millimeter wave scanners stems from a confluence of factors encompassing privacy concerns, fears surrounding ionizing radiation, and the acceptable detection efficacy offered by millimeter wave technology.

Initially, privacy issues hindered the widespread adoption of backscatter X-ray scanners. However, the subsequent apprehension regarding ionizing radiation further sidelined X-ray technology.

Regulations governing the use of ionizing radiation, such as Euratom, IRR17, and JOPA2004, are predicated on the Linear No Threshold (LNT) model, which asserts that any exposure to radiation carries inherent health risks. Consequently, X-ray systems encounter stringent limitations unless their deployment can be justified by a significant probability of threat detection.

Despite emerging evidence supporting hormesis — the notion that low doses of ionizing radiation may confer health benefits — entrenched fears perpetuated by the LNT model continue to influence regulatory frameworks. This dichotomy underscores a complex interplay between scientific understanding and regulatory policy within the realm of radiation safety.

Given the low likelihood of encountering terrorists during routine passenger screenings, the adoption of millimeter wave scanners, which operate without ionizing radiation, has become the preferred choice. These scanners offer detection capabilities while circumventing the regulatory constraints associated with X-ray technology.

It is noteworthy that X-ray Transmission Body Scanners persist in certain contexts, such as customs inspections and prison facilities, where there is a reasonable probability of detecting internal threats such as drug smuggling. In such instances, regulatory justifications for X-ray system usage have been granted under specific frameworks, such as JOPA2004.

In conclusion, the transition from backscatter X-ray units to millimeter wave scanners reflects a multifaceted interplay between technological capabilities, regulatory considerations, and evolving perceptions of radiation risk. This shift underscores the dynamic nature of aviation security measures and the imperative of balancing efficacy with safety and privacy concerns.

TSI: What role can technologies such as AI play in making airport body scanning more accurate and efficient?

Jentsch: Artificial Intelligence (AI) and other methods are being used to enhance accuracy and efficiency in all security screening technologies. But AI and other advanced methods are only as good as the quality and quantity of data collected and processed by a security scanner.

The internal resolution of a body and its data quality are critical elements to enable AI delivery of performance improvements. In this way, AI-powered automated threat recognition (ATR) software enables the automated detection of person-borne threats and anomalies more effectively than ever to deliver reduced false positives and improved detection rates. These AI algorithms can be trained to recognize a wide range of current and emerging threats to improve security and enhance checkpoint throughput and operational efficiency of people-screening technology in aviation security.

In addition, AI has enabled the development of new capabilities to make screening more inclusive and easier for more passengers, as it has made it possible to implement gender nonbinary screening and enhanced detection performance powered by AI, making screening more accurate and faster for all passengers. Future enhancements that AI technology may deliver include the ability to make screening of passengers with disabilities less invasive and may someday be able to screen passengers in wheelchairs.

Snezhina: The integration of AI into airport body scanning holds immense promise for enhancing accuracy and efficiency, yet it also presents challenges that must be navigated judiciously.

AI-based technologies excel in scenarios where detection tasks are well-defined, and threats can be clearly classified and marked during training. This is particularly advantageous in scenarios such as scanning for assembled firearms in non-dense baggage. However, challenges arise when dealing with disassembled weapons or when scanning for a wide range of potential threats simultaneously where the AI has not been ‘trained’ for those threats. The false alarm rate becomes a critical factor in determining the efficacy of machine vision, with low false alarms and high detection probability being prerequisites for its practical application.

In the context of body inspection, AI offers significant advantages, especially in conjunction with transmission X-ray technology. The relatively uniform nature of the human body simplifies the task for AI algorithms, particularly in discerning between biological structures and potential threats. By focusing on identifying non-human objects on the body, AI can streamline the inspection process, allowing operators to concentrate on anomalies rather than conducting exhaustive internal body analyses. While training operators to interpret complex biological structures can be challenging, machine vision simplifies this task significantly.

However, the integration of AI into security screening processes is not without its pitfalls. Operators may become overly reliant on AI, assuming that the absence of an alarm indicates the absence of threats. Yet, AI systems have inherent limitations, primarily dictated by the parameters of their training data. If an AI model is not trained to identify specific threats, it may fail to trigger an alarm even in the presence of a threat. This potential for oversight underscores the importance of incorporating complementary techniques such as Threat Incident Projection (TIP) to mitigate operator complacency.

In conclusion, while AI holds immense potential for revolutionizing airport body scanning, its implementation must be approached with caution. By leveraging its strengths in detecting predefined objects and complementing it with strategies to mitigate human error, AI can indeed enhance security screening efficiency and accuracy. However, careful consideration of its limitations and potential risks is imperative to ensure its integration yields positive outcomes in the realm of aviation security.

TSI: Can technology reduce the number of people needed for security screening work, at a time when help is hard to find?

Jentsch: Technology can indeed reduce the number of staff required in security screening operations. Advanced automated detection software can remove much of the burden from security operators by reducing false and nuisance alarms. This results in a higher pass-rate which reduces time-consuming alarm resolution pat-down procedures.

Fewer alarms mean fewer staff are required to resolve alarms. Beyond increased security and operational efficiencies, advanced technology also improves the passenger checkpoint security screening experience. Additionally, as part of the DHS Screening at Speed (SaS) Program, Rohde & Schwarz and its partners have developed technology that can automate and deliver self-service security screening. It utilizes the QPS201 with a passenger guidance system and access control gating solution, requiring minimal security staff to mainly provide direction and if required, to resolve alarms. As widely reported in major media coverage this month, this solution has been deployed at Harry Reid Las Vegas International Airport at the Transportation Security Administration’s (TSA) Innovation Checkpoint for a six-month ongoing trial assessment. It was reported that this demonstration system can substantially reduce the number of screening operators from twelve people down to five for these trials.

Snezhina: The role of technology in reducing the number of personnel required for security screening work, particularly during times of scarcity, is a multifaceted consideration influenced by task complexity and the efficacy of technological solutions.

While technology, particularly AI, holds promise in streamlining security screening processes, its implementation hinges on the complexity of the task at hand. AI’s effectiveness is most pronounced when tasked with aspects of the screening process where it can deliver close to 100% probability results with a negligible false alarm rate. This doesn’t necessarily translate to a reduction in personnel numbers but rather a refinement in the qualifications required. AI can effectively guide operators, simplifying their tasks and enhancing overall efficiency. However, it’s premature to rely solely on machine vision algorithms given current technological limitations.

Beyond mere reductions in staffing, the crux lies in technology’s potential to enhance the Probability of Detection (PoD) of threat items. Irrespective of the workforce size, certain threats may evade detection through manual searches, particularly those concealed internally.

A system boasting a high PoD could indeed lead to a significant reduction in staffing requirements. However, this must be balanced with the risk of a heightened False Alarm Rate (FAR), wherein alarms are triggered for non-threatening items. Striking this balance is critical, often requiring optimization of the Receiver Operating Curve (ROC) to find equilibrium between PoD and FAR.

The impact of technology on staffing levels is palpable in people screening, where technologies such as millimeter-wave body scanners play a pivotal role. Depending on the FAR required to achieve an acceptable PoD, the need for manual pat-downs may vary. High FAR scenarios may necessitate numerous manual pat-downs, potentially escalating staffing requirements, especially considering same-sex pat-down protocols. Conversely, a low FAR at the requisite PoD could effectively reduce the demand for personnel.

In conclusion, while technology presents opportunities to enhance security screening efficiency and reduce staffing requirements, its implementation must be carefully calibrated to balance PoD and FAR considerations. Achieving this equilibrium is crucial to optimizing security screening processes in the face of staffing challenges.

TSI: What other trends are affecting the airport body scanner market, in terms of products and client needs?

Jentsch: As passenger volumes continue to increase at airports around the world and as airport security staffing remains challenged, the airport body scanner market is being driven by the need for faster, more efficient and minimally intrusive security screening for all passengers.

In addition, technology needs to adapt to process a diverse range of passengers. The number of aging and disabled travelers is growing and there is the opportunity, with new technology, to make security screening easier and faster for all travelers.

Working with a wide range of our customers, we are being called upon to optimize the R&S QPS systems’ screening capability for specific use cases. At Rohde & Schwarz we are able to develop specialty software to adapt, both the R&S QPS201 and the R&S QPSWALK scanning software, for specific use cases to, for example, facilitate airport employee screening and enable other high-volume security screening operations.

Snezhina: The airport body scanner market is undergoing significant shifts influenced by a multitude of factors ranging from technological advancements to evolving client needs and regulatory standards.

On the technological front, the prevalence of airport security procedures presents challenges in terms of efficiency and efficacy. While some airports still rely on traditional metal detectors, many have adopted state-of-the-art millimeter-wave scanners, which are increasingly becoming the preferred choice due to their superior detection capabilities when compared to metal detectors. Moreover, there’s a growing trend towards non-stop inspection procedures, streamlining the scanning process to minimize delays and queues, akin to passing through a metal detector seamlessly.

However, mm-wave scanners have limitations, particularly in their inability to provide internal imaging. This shortfall has paved the way for the potential resurgence of transmission X-ray body scanners, particularly those employing ultra-low doses of radiation. The legality of such scanners is a critical consideration, with regulatory standards like ANSI 43.17-2009 governing radiation safety in the United States. While some countries have stringent regulations against X-ray usage, advancements in technology and safety measures may pave the way for broader acceptance.

Moreover, the dynamic nature of aviation security demands equipment capable of addressing both existing and emerging threats. Suppliers are thus focused on enhancing the Probability of Detection (PoD) while reducing the False Alarm Rate (FAR) and streamlining scan duration to enhance throughput and passenger experience.

In essence, the future of airport body scanning lies in striking a delicate balance between technological innovation, regulatory compliance, and addressing evolving security threats. Advancements in AI, coupled with improvements in scanning technology, hold the promise of revolutionizing airport security, ensuring the safety and efficiency of air travel for passengers worldwide.

TSI: What body scanning products are you offering that address these trends and needs?

Jentsch: Unlike legacy body scanners, Rohde & Schwarz has developed on-person screening technology specifically to meet the needs of modern security screening operations. Both of our solutions utilize safe, high-definition mmW technology and both of our products utilize sophisticated AI and machine learning to continually improve the detection performance for increased throughput and improved passenger experience.

Our flagship solution, the R&S QPS201 Ultra High Definition (UHD) scanner, is widely deployed world-wide and has redefined the standard for on-person screening. The R&S QPS Walk2000 is our newest product in security scanners and utilizes ultra-wideband technology to deliver unmatched high-fidelity screening without the need for passengers and/or airport or other employees to divest outerwear and other clothing. The scanner screens continuously, without the need to stop, as required in typical checkpoint screening operations. For the first time, the R&S QPS Walk2000’s high-volume and high-definition on-person security screening technology delivers the capabilities security operators need.

Snezhina: Since pioneering the world’s first Security Transmission X-ray Body Scanner in 1999, LINEV Systems has remained dedicated to continuous enhancement in design, development, and manufacturing of X-ray Transmission Body Scanners. These scanners are currently deployed across various sectors, including customs, prisons, diamond and precious metal mines, among others. LINEV Systems has supplied well over 1,000 units of different types, including torso, whole body, dual-view, and portable versions, all of which are readily available.

We offer unique low-dose transmission X-ray body scanners for airport security and customs control. We provide two main modifications: the full-body scanner, CLEARPASS, and the partial-body compact scanner, CLEARPASS CI. Both models are compatible with ANSI43.17-2009 regulations. Additionally, they boast extensive AI and machine vision functionality, offering very high throughput alongside the best X-ray image quality available on the market.

All of our body scanners feature AI and machine vision functionality. Threat visualization can be configured to display detailed information or in a privacy protection mode, similar to mm-wave scanners. Furthermore, our transmission X-ray body scanners are equipped with machine vision algorithms capable of distinguishing between different materials, such as clothes (green), electronics (blue), weapons (red), or unidentified objects (brown).

LINEV Systems is eagerly anticipating the alignment of the aviation market and radiation regulators with the significant benefits their products offer to security, and even to people’s health.

TSI: Finally, what advances are on the horizon for airport body scanners?

Jentsch: The future of body scanners promises even greater efficiency and comfort. For example, as technology continues to evolve, walk-through or walk-by, on-person screening will be possible in airport checkpoints and meet the requirements of other high volume security operations like the screening of aviation workers. Moreover, as scanner technology and AI make further advancements, mmW systems will become more precise with far fewer false alarms and better able to detect a wider range of smaller threats and contraband. This means that there will be less reliance for security operators and passengers may have self-service security screening options available to them.

Another key development on the horizon that passengers will love is the addition of footwear scanning to body scanners. Rohde & Schwarz and other manufacturers are exploring shoe scanner technologies that will eliminate the need for passengers to remove their shoes for security screening.

The challenges of screening people in airport security screening and the myriad of other use cases and missions are well known and Rohde & Schwarz has developed body scanner technology to address the needs of aviation security screening operations, but we are continuing to innovate. We have a few on-going research and development initiatives underway to add long-awaited capabilities to make on-person security screening more accurate, faster and easier for all passengers and security operators.

Strengthening Cargo Security Across the Supply Chain

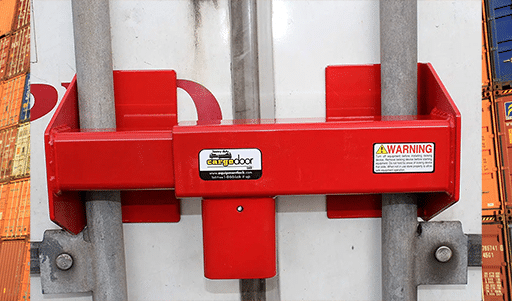

Cargo security keeps goods safe. On freighters, docks, trucks, railcars, warehouses, and ports, cargo shipments are vulnerable to theft during several stages of the transit process. If a container isn’t properly and securely sealed, it can be opened many times during transit with its contents stolen and easily sold on the black market.

Stolen cargo can cost suppliers thousands to upwards of millions of dollars. An estimated $223 million in cargo was stolen during 2022, according to a new analysis by Verisk’s CargoNet. CargoNet recorded 1,778 supply chain risk events in the U.S. and Canada in 2022, a 15% increase from 2021. The average value of cargo stolen in an event was $214,104, CargoNet said.

The consequences of not sufficiently protecting cargo can be devastating, ranging from financial loss and damaged reputation to long-term, intricate legal disputes. And, today’s thieves are now highly tech-savvy and constantly developing modern ways and strategies to steal cargo from shippers. Because of this, more advanced container security measures have been developed helping to reduce burglaries and resulting theft claims.

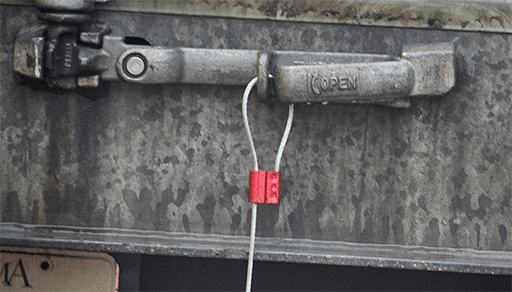

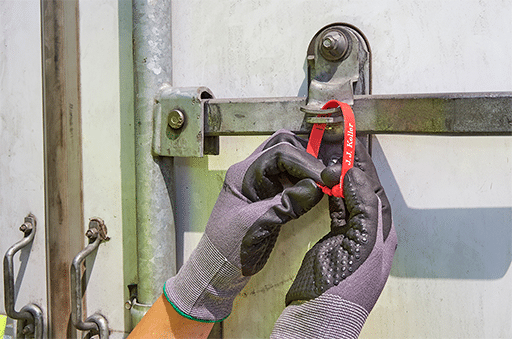

J. J. Keller image.

Best Practices

Josh Lovan, industry business advisor at J. J. Keller & Associates, Inc., Fort Smith, Arkansas, explains that ensuring cargo security during transit is crucial and cites the following best practices to make this happen:

• Use High-Quality Seals: Invest in security seals made of durable materials like metal or heavy-duty plastic. Avoid using seals that can be easily tampered with or broken.

• Proper Application: Apply seals correctly, ensuring they are securely fastened to prevent tampering or unauthorized access.

• Unique Identification: Use seals with unique serial numbers or barcodes for easy tracking and identification. This helps in verifying the integrity of the cargo.

• Regular Inspections: Conduct routine inspections of seals and locks throughout the transit process to detect any signs of tampering or damage.

• Multiple Layers of Security: Utilize multiple layers of security, such as container locks in addition to seals, to provide added protection against theft or unauthorized access.

• Security Protocols: Implement strict security protocols and procedures for handling, loading, and unloading cargo to minimize the risk of tampering or theft.

• Monitoring and Tracking: Employ GPS tracking systems or other monitoring technologies to track the location and status of cargo in real-time, providing visibility throughout transit.

• Training and Awareness: Train personnel involved in handling cargo on security protocols and the importance of maintaining the integrity of seals and locks.

J. J. Keller images.

Seals and Locks

Security seals and container locks are requisite to keep cargo secure in transit. Not all seals and locks are created equally. Each type of seal or lock offers different levels of security and suitability for specific applications.

Different industries employ a variety of security seals tailored to their specific needs and cargo requirements. For instance, the transportation industry relies on heavy-duty seals like bolt seals or cable seals to secure shipping containers and trailers, safeguarding valuable goods during transportation. Industries dealing with retail and consumer goods prioritize tamper-evident seals with unique identification features to maintain the integrity of products as they move from manufacturers to retailers.

“Pharmaceutical and healthcare companies often opt for advanced seals equipped with RFID technology, enabling real-time tracking and monitoring of sensitive pharmaceutical products to comply with stringent regulatory requirements and maintain product integrity,” Lovan says. “The food and beverage industry may utilize seals designed to withstand environmental factors and provide clear evidence of tampering, ensuring food safety and compliance with regulatory standards.”

It’s essential to assess your cargo security requirements and choose the appropriate seals and locks accordingly. Overall, Lovan believes the choice of security seals varies across industries based on factors such as cargo value, sensitivity, transportation mode, and regulatory compliance needs, with each industry selecting seals that best meet their unique security requirements. He cites the following types of security seals and container locks available for cargo security.

• Bolt Seals: These are high-security seals that require bolt cutters to remove, making them difficult to tamper with.

• Cable Seals: Made of steel cables, these seals are flexible and suitable for securing irregularly shaped items. They offer high tensile strength and are resistant to tampering.

• Bar Seals: These seals feature a metal bar that is inserted into a locking mechanism, providing a secure closure for containers and trailers.

• Plastic Seals: These seals are commonly used for securing shipping containers, trucks and trailers. They are lightweight, cost-effective, and offer tamper-evident features.

• RFID Seals: These seals are equipped with radio frequency identification (RFID) technology, allowing for electronic tracking and monitoring of cargo in real-time.

• Kingpin Locks: These locks are installed on the kingpin of a trailer, preventing unauthorized access to the container when it is attached to a truck.

• Wheel Locks: These locks are placed on the wheels of trailers or containers to prevent them from being moved or accessed without authorization.

Below are criteria for determining the best seal for your application:

• Determine if an indicative or barrier seal is required.

• If using a barrier seal, determine what strength level is needed.

• Make sure that the seal type that you choose fits the device.

• Choose a seal that has the appropriate level of strength and security.

• Measure seal cost vs. security risks.

• Use a manageable locking system considering the tools and resources you have at your disposal.

• Consider the durability of the seal in relation to its environment.

• Below are criteria for handling and use of cargo seals:

• Know the locking procedure, design and features of this seal.

• Give seals only to authorized persons.

• Document all seals taken from storage.

• Apply seals securely according to instructions for this model. Note any problems or unusual visible damage like bent hasps, worn holes, unusual conditions or cosmetic damage to seals in applying.

• Destroy seals completely after use. Do not simply toss them out or leave parts or cut seals intact; or under conditions where they may be collected by others. Ideally it is good practice to return them to a central facility for destruction by an authorized and trained inspector.

Reliable Line of Defense

While these locks and seals are a reliable line of defense, criminals can compromise security seals and container locks through various methods such as brute force, and tools like bolt cutters to break seals or manipulate locks. They also employ tampering techniques, like duplicating seals or picking locks, to gain unauthorized access to cargo.

C-TPAT stands for Customs-Trade Partnership Against Terrorism. Founded shortly after the terrorist attacks of September 11, 2001, C-TPAT is a voluntary, collaborative effort between U.S. Customs and Border Protection (CPB) and commercial shippers to develop comprehensive cargo security programs for imports into the U.S. To further prevent theft, C-TPAT seals are security seals affixed to cargo containers by C-TPAT certified entities, signifying compliance with rigorous security standards. These seals serve as an indicator of a secure supply chain, facilitating expedited customs clearance and reducing the risk of cargo tampering or terrorism-related threats. C-TPAT seals may feature unique identification numbers or barcodes, allowing for easy tracking and verification of cargo integrity.

GPS Tracking

With numerous companies and transportation methods involved throughout the transportation chain, pinpointing when and where a cargo security issue occurred can be daunting. Implementing a GPS tracking solution on cargo shipments provides suppliers with the ability to track their cargo throughout the entire journey, adding invaluable insight and security.

“With so many transportation methods and entities involved, cargo can be lost or delayed along the way,” says Jeff Karg, director of marketing and communications, PassTime, Littleton, Colo. GPS tracking devices for cargo shipments give the supplier their own tracking solution and are not reliant on the varying and sometimes non-exist tracking solutions from their transportation providers.”

Solutions like PassTime’s battery-powered Encore, are completely self-powered, can last up to five years without recharging, and at the size of a deck of cards, can quickly and easily be placed on just about any cargo shipment.

“Utilizing battery-powered GPS tracking solutions on the cargo itself means suppliers know if their cargo is still in transit, or more importantly, if it isn’t,” Karg says. “Locks and seals are an important aspect of cargo security. However, if the cargo container itself is lost those safeguards may have limited impact. Adding an additional layer of security, like a GPS tracking solution, can provide unparalleled visibility, control and protection to locate and recover missing cargo.”

Smart Containers

Smart containers are equipped with sensors that can detect intrusions like unauthorized door openings as well as anomalies such as a sudden change in container pressure or temperature (like when a hole is cut into the side wall of a container) that could indicate a breach.

Smart containers also have other integrated sensors such as GPS as well as additional internal sensors to measure the condition of the cargo inside. Data from the container’s sensors are either logged on a data module within the container, or it’s broadcast to a central monitoring platform via handheld readers, fixed scanners, or GSM/cellular connections.

Another, probably more viable option to (expensive) smart containers is the use of portable smart sensor kits that can be fixed to/within any standard container or truck trailer. These “smart kits” can turn any shipping container, truck trailer, or rail car into a “smart container,” giving logistics operations greater supply chain visibility for high-value cargo like pharmaceuticals, volatile chemicals, frozen food and other cold chain products.

The Human Element

Most theft crimes are not investigated because of manpower issues, so it is imperative that carriers take the necessary measures to prevent theft. Provide security training to all personnel, because everyone should be involved with protecting customer freight and company assets. Lovan says drivers can proactively deter theft by adopting the following prevention measures:

• Check the cargo seal and padlock during pre-trip and after being away from the unit.

• Never leave the tractor running when unattended.

• Always lock the doors and roll up windows when away from tractor.

• Always park in well-lit areas where other motorists are present.

Fleets can deter theft by implementing the following security polices during closed hours:

• Ensure trailers are docked, butted, and blocked at the terminal.

• Utilize kingpin locks for trailers that contain high value freight.

• Ensure that alarm systems are functional by conducting weekly tests.

• Utilize GPS technology to geofence equipment on the yard.

While no cargo being transported is completely immune to the risk of theft, the right technology will help to mitigate these problems to a great extent and help to ensure safe transportation of cargo. Anticipate and use security developments to your advantage, stay one step ahead and keep your cargo secure.

Building Resilience Against Critical Events

Critical events can affect any transport operator. Accidents, problems with infrastructure including vandalism, fires — such as those seen recently on electric buses in London — extreme weather events and cyberattacks have an immediate and often highly disruptive impact. While many incidents are resolved quickly, the knock-on effect on the reputation of the operator can be long-lasting, inconveniencing employees and passengers, and, in extreme cases, even threatening their lives.

It is therefore essential for transport organizations to build in resilience measures. This is, in part, the ability to anticipate the types of emergencies that might arise and adopt practices that minimize the impact of these crisis events on their operations. This type of approach ensures the safety of their employees and passengers and assists in resuming normal services quickly.

The success of operational resilience relies on several factors, the first of which is corporate culture. An organization’s resilience reflects the resiliency of its people, so public transport operators must invest in training programs, mentoring, and delivering resources that are inclusive for employees, and promote their well-being. Employees who are engaged and listened to will be better able to manage emergencies and equipped to confidently put practices in place to minimize disruption. Adopting an approach of employee collaboration through which teams and individuals are recognized for their successes and able to learn from their mistakes helps to cultivate collaboration and enables better teamwork in a crisis.

Continuously Assess Potential Risk

Proactive risk management coupled with agreed contingency plans that are regularly assessed and updated is essential. A list of the appropriate experts, technicians and helpers should be drawn up and these will be the first port of call when a critical event occurs. If companies fail to communicate in a timely manner during a crisis, they will lose control of the incident and the agreed response plan. Aligning actions to the right people ensures clarity of message, averts rumors, such as on social media, and keeps employees and passengers updated with accurate and timely information.

A comprehensive communications plan for use during a critical incident should be devised by transport operators. This outlines processes and those with responsibility for communication, who talks to whom and when, and what information they share. In addition to internal contacts, there may be external groups, such as passengers, partners of employees, or the public, that will require communications and updates. As public transport companies operate critical infrastructure, there may also be an obligation to report to the authorities.

Planning saves time and effort in an emergency. Messaging templates, for example, can be created in advance to help employees communicate efficiently and accurately. These will need to contain specific information to suit a variety of audiences and situations, but key messages must be consistent and not contradictory so everyone involved can be kept on the same page. Transport operators should plan for multimodal communication. The more channels they use, the more likely they are to reach all audiences. Ideally, messages should be sent through the most used channels today such as SMS texts, push messages, email, and voice messages and on both personal and work landlines and mobile phones. Practicing the procedures that have been agreed upon will allow transport operators to ensure they work efficiently without the pressure of a crisis. Any problems can be identified and addressed.

Building Resilience with Technology

Organizational resilience can be enhanced immeasurably by technology. Transport operators will benefit from an integrated critical event management (CEM) software solution that connects business continuity, disaster recovery, and risk management tools. This allows them to assess risk, seamlessly disseminate information across teams, and avoid disruptions that get in the way of responding quickly to a critical event. At the core of a CEM platform is a data hub that collates all the information relevant to an emergency and manages all the necessary processes.

Information that informs a CEM platform ranges from IoT device data monitoring traffic infrastructure and vehicles through to employee location data. It also includes police channels on social media, traffic information, or severe weather warnings. The platform brings this data together and visualizes it so transport companies can be quickly alerted to likely crises, assess the impact on their own systems, and initiate responses. From this, teams with responsibility for communicating critical events can coordinate activities, teams, and resources within a single application.

Emergency processes can be quickly implemented and controlled in a CEM solution in the form of rules, guidelines, and templates and it will automate those processes using a workflow system. This reduces the time that might be lost to manual activities. The CEM platform should support two-way communication allowing people to respond, which is helpful in terms of knowing who is safe, where people still need help, and whether the level of response needs to be escalated.

Transport operators face many risks but with intelligence, strategic planning and a robust crisis communication plan in place, they will be able to maintain operational resilience and protect both employees and passengers in the event of a crisis.

Tracy Reinhold is chief security officer at Everbridge. He is responsible for advancing Everbridge’s enterprise-level security strategy, as well as working closely with customers and partners to optimize their organizational approach to managing and responding to critical events.

Two Offers for Warehouse Logistics

With the LogiDrive solution space, NORD offers its warehouse logistics customers two industry-optimized drive concepts. LogiDrive Advanced and LogiDrive Basic both impress with their low weight and compact installation space. In addition, they are optimized for different factors.

Chain and roller conveyors, belt and pallet conveyors, container and overhead conveyors: In warehouse logistics, they all require reliable drives with sufficient power for the corresponding application. This is guaranteed by both solutions from the drive specialist NORD. Furthermore, both feature maximum user-friendliness, easy wiring, low weight and compact installation space. What sets them apart: LogiDrive Advanced was optimized for energy efficiency and LogiDrive Basic with regards to costs.

The drive solutions in detail:

• LogiDrive Advanced

o Highly efficient IE5+ synchronous motor

o Decentralised NORDAC ON+ frequency inverter, which was specially designed for combination with the IE5+

o A gear unit from the NORD portfolio

• LogiDrive Basic

o IE3 asynchronous motor

o Decentralized NORDAC ON frequency inverter

o A gear unit from the NORD portfolio

According to the customer’s requirements: Focus on costs or energy efficiency

The LogiDrive Advanced drive solution ensures maximum energy efficiency and thus achieves high savings in CO2 emissions. It achieves its very high efficiency via large speed and load ranges, and allows for a variant reduction. This is particularly attractive for large systems with numerous drives: Fewer drive variants in a system result in streamlined logistics, warehouse and service processes and thus in reduced administrative costs.

The components of the LogiDrive Basic are perfectly matched. They meet all essential warehouse application standards and impress with a large adjustment range. This drive solution does not offer maximum efficiency but features low investment costs.

Whether LogiDrive Advanced or LogiDrive Basic: The decision is determined by the specific application requirements. Either way, the user receives a perfectly industry-optimized solution, including a frequency inverter with integrated multi-protocol Ethernet interface. Furthermore, both solutions are equipped with all international certifications and can thus be used worldwide, which is important for globally active companies.

NORD at Passenger Terminal Expo 2024 in Frankfurt

NORD DRIVESYSTEMS has specially optimized a product series from the LogiDrive solutions space for the requirements of airport logistics. The specialist will present its drives at the leading trade fair for the airport and air transport industry from 16 to 18 April 2024.

Luggage items of different weights often have to be transported over long distances: This places very special demands on the drive technology. NORD has specially optimised a product series from its LogiDrive solution space for applications such as tray, belt or roller conveyors. The three system solutions are all lightweight and feature compact installation space, but also provide different advantages:

• LogiDrive Basic

o Consists of an IE3 asynchronous motor, the decentralised NORDAC ON frequency inverter and a gear unit from the NORD portfolio

o Convinces with low investment costs and a wide adjustment range

• LogiDrive Advanced

o Consists of an IE5+ synchronous motor, the decentralised NORDAC ON+ frequency inverter and a gear unit from the NORD portfolio

o Operates with high energy efficiency, saves CO2 emissions and also allows for a variant reduction

• LogiDrive Advanced with DuoDrive

o Consists of the DuoDrive geared motor and the decentralised NORDAC ON+ frequency inverter

o Provides the advantages of the LogiDrive Advanced plus low maintenance effort

LogiDrive Advanced and LogiDrive Advanced with DuoDrive are especially advantageous in large conveyor systems with numerous drive units. The particularly efficient drive solutions enable enormous savings in terms of energy costs and therefore also CO2 emissions. The reduction of various drive variants in a large system also reduces costs. A variant reduction minimises administrative costs and streamlines production, logistics, storage and service processes.

Furthermore, NORD supports its customers in finding the most energy-efficient drive solution for their individual application. The NORD ECO service checks installed drives with regard to energy efficiency, dimensioning and number of variants. Based on this analysis, customers receive an energy efficiency concept that is entirely tailored to the requirements of the respective application.

NORD DRIVESYSTEMS will present its drive solutions for airport logistics from 16 to 18 April 2024 at Passenger Terminal Expo in Frankfurt. You will find the company at Stand D300.